CHAPTER 5

Mechanical Properties of Wood

David E. Kretschmann, Research General Engineer

5–1

The mechanical properties presented in this chapter were

obtained from tests of pieces of wood termed “clear” and

“straight grained” because they did not contain characteris-

tics such as knots, cross grain, checks, and splits. These test

pieces did have anatomical characteristics such as growth

rings that occurred in consistent patterns within each piece.

Clear wood specimens are usually considered “homoge-

neous” in wood mechanics.

Many of the mechanical properties of wood tabulated in this

chapter were derived from extensive sampling and analysis

procedures. These properties are represented as the aver-

age mechanical properties of the species. Some properties,

such as tension parallel to the grain, and all properties for

some imported species are based on a more limited number

of specimens that were not subjected to the same sampling

and analysis procedures. The appropriateness of these latter

properties to represent the average properties of a species

is uncertain; nevertheless, the properties represent the best

information available.

Variability, or variation in properties, is common to all

materials. Because wood is a natural material and the tree

is subject to many constantly changing inuences (such as

moisture, soil conditions, and growing space), wood proper-

ties vary considerably, even in clear material. This chapter

provides information, where possible, on the nature and

magnitude of variability in properties.

This chapter also includes a discussion of the effect of

growth features, such as knots and slope of grain, on clear

wood properties. The effects of manufacturing and service

environments on mechanical properties are discussed, and

their effects on clear wood and material containing growth

features are compared. Chapter 7 discusses how these

research results have been implemented in engineering

standards.

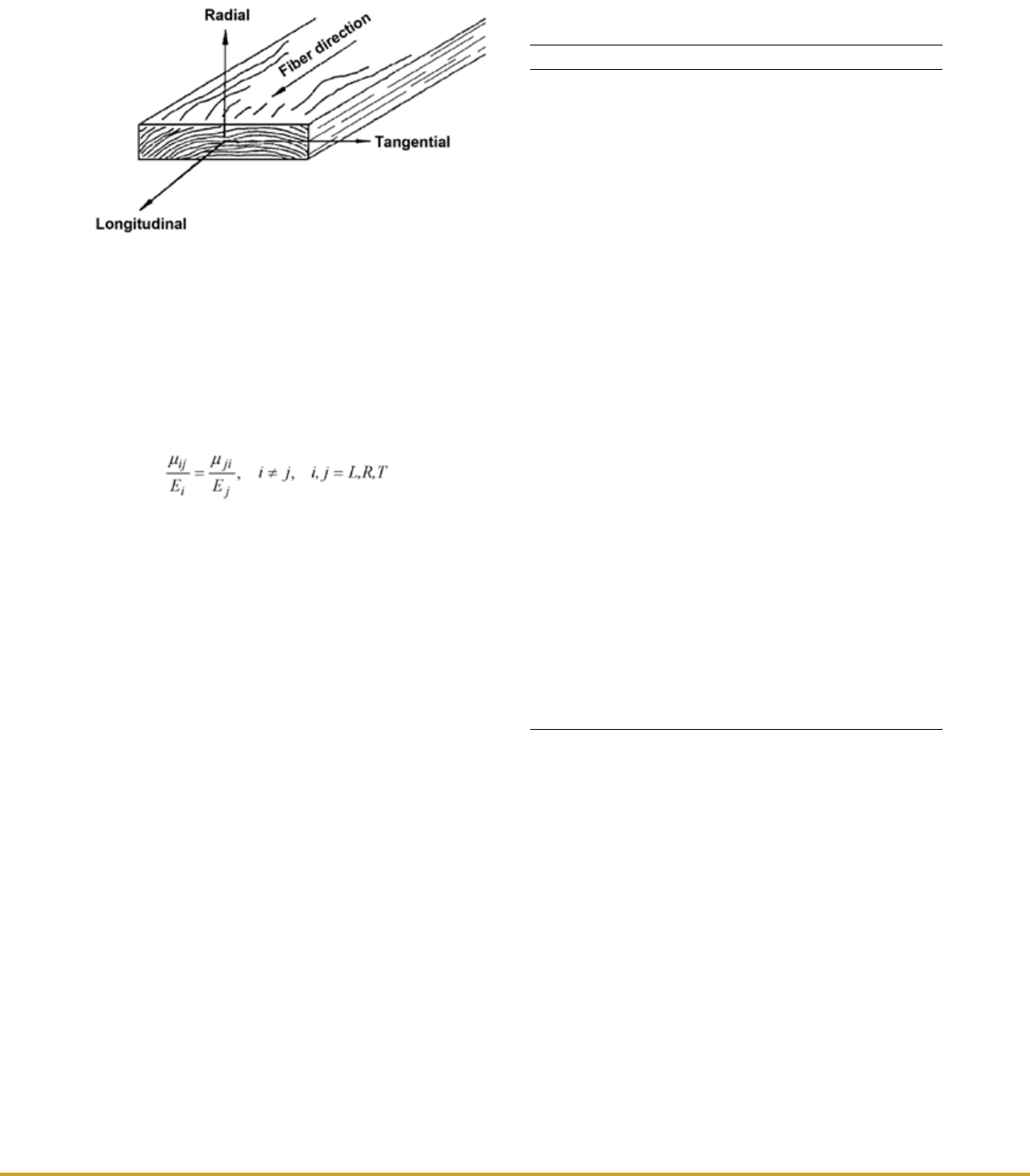

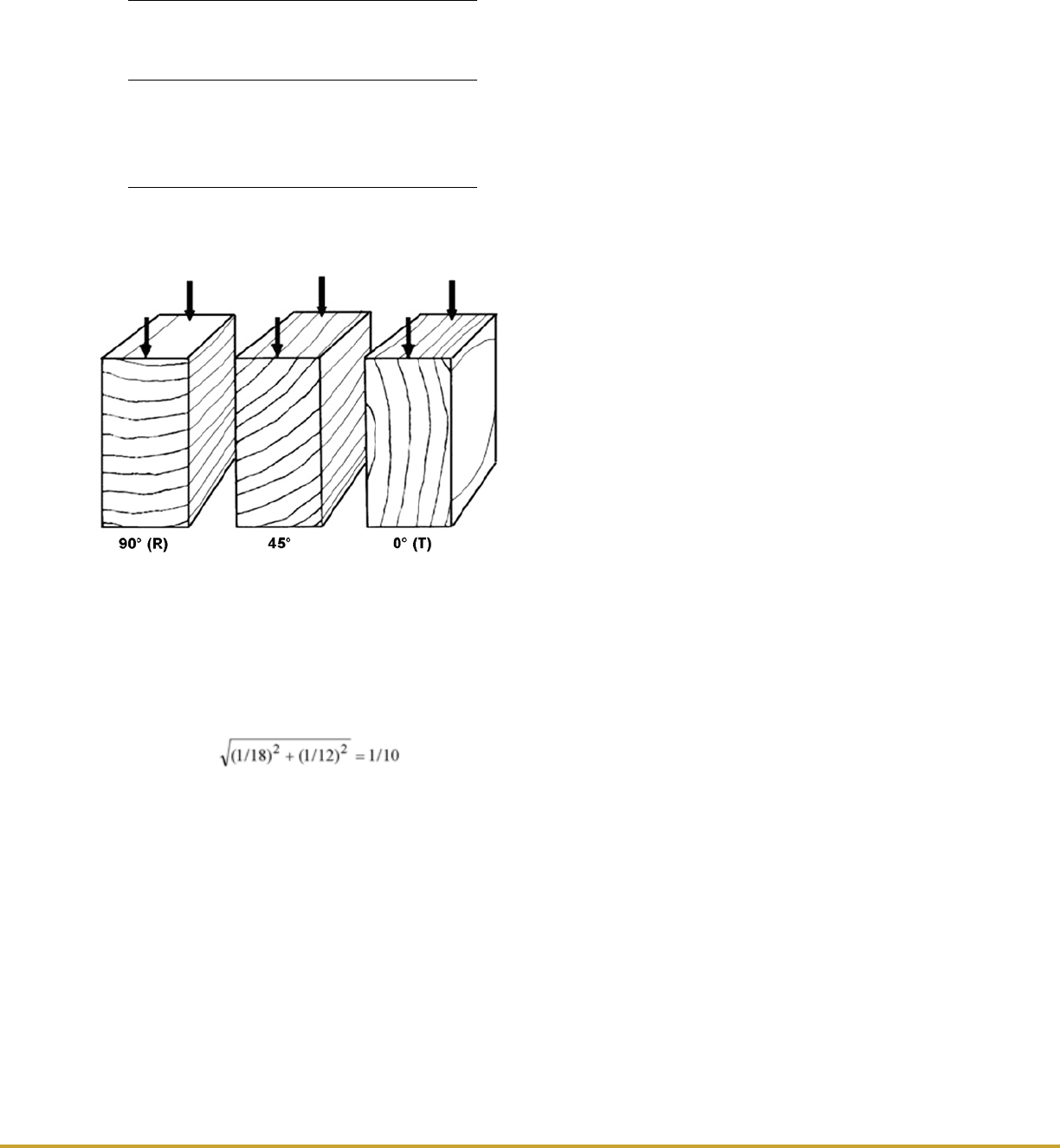

Orthotropic Nature of Wood

Wood may be described as an orthotropic material; that is,

it has unique and independent mechanical properties in the

directions of three mutually perpendicular axes: longitudi-

nal, radial, and tangential. The longitudinal axis L is parallel

to the ber (grain); the radial axis R is normal to the growth

rings (perpendicular to the grain in the radial direction); and

the tangential axis T is perpendicular to the grain but tangent

to the growth rings. These axes are shown in Figure 5–1.

Contents

Orthotropic Nature of Wood 5–1

Elastic Properties 5–2

Modulus of Elasticity 5–2

Poisson’s Ratio 5–2

Modulus of Rigidity 5–3

Strength Properties 5–3

Common Properties 5–3

Less Common Properties 5–15

Vibration Properties 5–17

Speed of Sound 5–17

Internal Friction 5–17

Mechanical Properties of Clear Straight-Grained

Wood 5–21

Natural Characteristics Affecting Mechanical

Properties 5–26

Specific Gravity 5–26

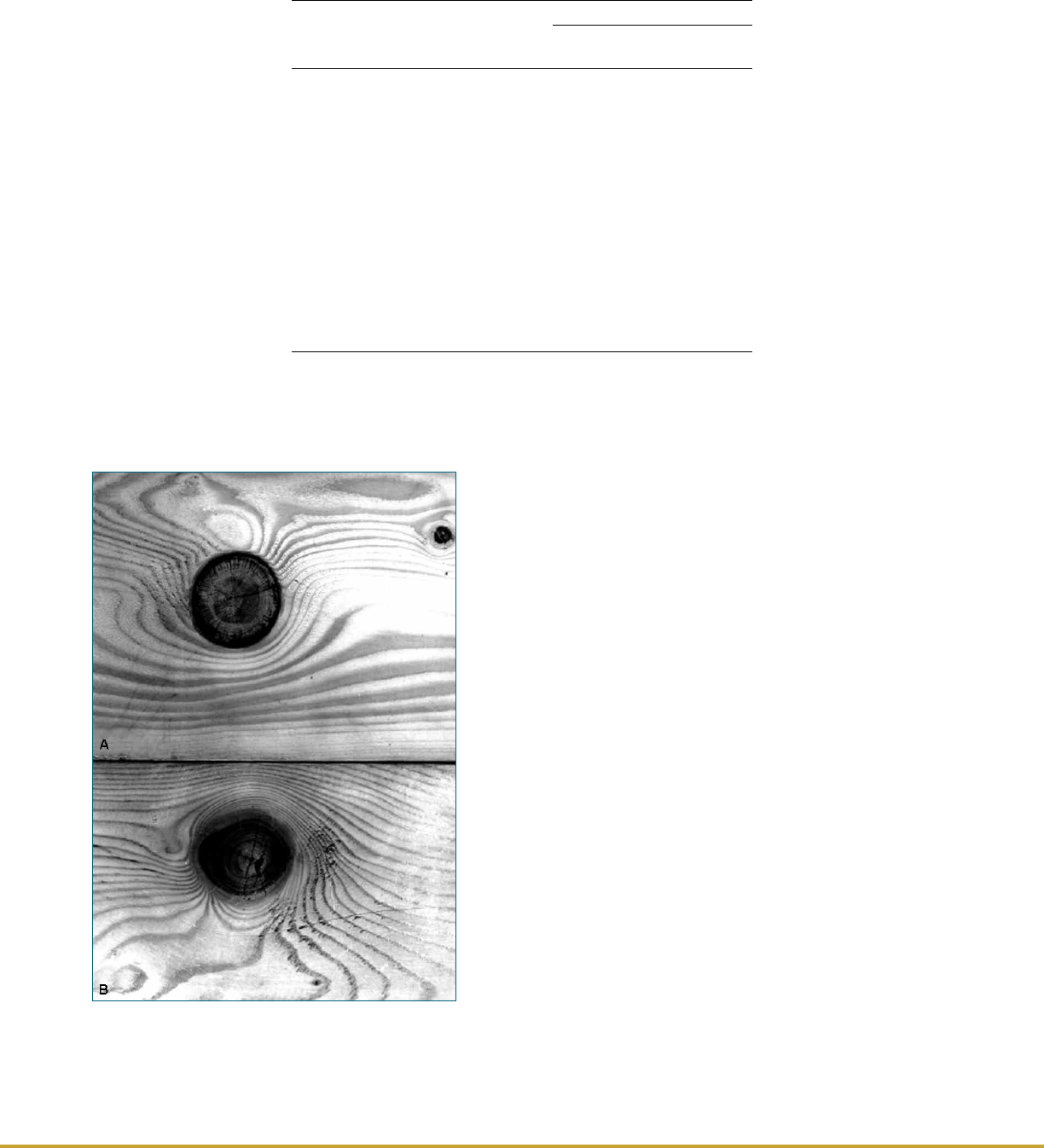

Knots 5–26

Slope of Grain 5–28

Annual Ring Orientation 5–31

Reaction Wood 5–31

Juvenile Wood 5–32

Compression Failures 5–33

Pitch Pockets 5–33

Bird Peck 5–33

Extractives 5–34

Properties of Timber from Dead Trees 5–34

Effects of Manufacturing and Service

Environments 5–34

Temperature 5–35

Time Under Load 5–38

Aging 5–41

Exposure to Chemicals 5–41

Chemical Treatment 5–41

Nuclear Radiation 5–43

Mold and Stain Fungi 5–43

Decay 5–43

Insect Damage 5–44

Literature Cited 5–44

Additional References 5–44

5–2

Elastic Properties

Twelve constants (nine are independent) are needed to de-

scribe the elastic behavior of wood: three moduli of elastic-

ity E, three moduli of rigidity G, and six Poisson’s ratios μ.

The moduli of elasticity and Poisson’s ratios are related by

expressions of the form

(5–1)

General relations between stress and strain for a homoge-

neous orthotropic material can be found in texts on

anisotropic elasticity.

Modulus of Elasticity

Elasticity implies that deformations produced by low stress

are completely recoverable after loads are removed. When

loaded to higher stress levels, plastic deformation or failure

occurs. The three moduli of elasticity, which are denoted

by E

L

, E

R

, and E

T

, respectively, are the elastic moduli along

the longitudinal, radial, and tangential axes of wood. These

moduli are usually obtained from compression tests; how-

ever, data for E

R

and E

T

are not extensive. Average values

of E

R

and E

T

for samples from a few species are presented in

Table 5–1 as ratios with E

L

; the Poisson’s ratios are shown

in Table 5–2. The elastic ratios, and the elastic constants

themselves, vary within and between species and with mois-

ture content and specic gravity.

The modulus of elasticity determined from bending, E

L

,

rather than from an axial test, may be the only modulus of

elasticity available for a species. Average E

L

values obtained

from bending tests are given in Tables 5–3 to 5–5. Repre-

sentative coefcients of variation of E

L

determined with

bending tests for clear wood are reported in Table 5–6. As

tabulated, E

L

includes an effect of shear deection; E

L

from

bending can be increased by 10% to remove this effect ap-

proximately. This adjusted bending E

L

can be used to deter-

mine E

R

and E

T

based on the ratios in Table 5–1.

Poisson’s Ratio

When a member is loaded axially, the deformation perpen-

dicular to the direction of the load is proportional to the

deformation parallel to the direction of the load. The ratio

of the transverse to axial strain is called Poisson’s ratio.

The Poisson’s ratios are denoted by μ

LR

, μ

RL

, μ

LT

, μ

TL

, μ

RT

,

and μ

TR

. The rst letter of the subscript refers to direction

of applied stress and the second letter to direction of lateral

deformation. For example, μ

LR

is the Poisson’s ratio for

deformation along the radial axis caused by stress along

the longitudinal axis. Average values of experimentally de-

termined Poisson’s ratios for samples of a few species are

given in Table 5–2. The ideal relationship between Poisson’s

ratio and the moduli of elasticity given in Equation (5–1) are

not always closely met. Two of the Poisson’s ratios, μ

RL

and

μ

TL

, are very small and are less precisely determined than

are those for other Poisson’s ratios. Poisson’s ratios vary

within and between species and are affected by moisture

content and specic gravity.

Figure 5–1. Three principal axes of wood with respect to

grain direction and growth rings.

Table 5–1. Elastic ratios for various species at

approximately 12% moisture content

a

Species E

T

/E

L

E

R

/E

L

G

LR

/E

L

G

LT

/E

L

G

RT

/E

L

Hardwoods

Ash, white 0.080 0.125 0.109 0.077 —

Balsa 0.015 0.046 0.054 0.037 0.005

Basswood 0.027 0.066 0.056 0.046 —

Birch, yellow 0.050 0.078 0.074 0.068 0.017

Cherry, black 0.086 0.197 0.147 0.097 —

Cottonwood, eastern 0.047 0.083 0.076 0.052 —

Mahogany, African 0.050 0.111 0.088 0.059 0.021

Mahogany, Honduras 0.064 0.107 0.066 0.086 0.028

Maple, sugar 0.065 0.132 0.111 0.063 —

Maple, red 0.067 0.140 0.133 0.074 —

Oak, red 0.082 0.154 0.089 0.081 —

Oak, white 0.072 0.163 0.086 — —

Sweetgum 0.050 0.115 0.089 0.061 0.021

Walnut, black 0.056 0.106 0.085 0.062 0.021

Yellow-poplar 0.043 0.092 0.075 0.069 0.011

Softwoods

Baldcypress 0.039 0.084 0.063 0.054 0.007

Cedar, northern white 0.081 0.183 0.210 0.187 0.015

Cedar, western red 0.055 0.081 0.087 0.086 0.005

Douglas-fir 0.050 0.068 0.064 0.078 0.007

Fir, subalpine 0.039 0.102 0.070 0.058 0.006

Hemlock, western 0.031 0.058 0.038 0.032 0.003

Larch, western 0.065 0.079 0.063 0.069 0.007

Pine

Loblolly 0.078 0.113 0.082 0.081 0.013

Lodgepole 0.068 0.102 0.049 0.046 0.005

Longleaf 0.055 0.102 0.071 0.060 0.012

Pond 0.041 0.071 0.050 0.045 0.009

Ponderosa 0.083 0.122 0.138 0.115 0.017

Red 0.044 0.088 0.096 0.081 0.011

Slash 0.045 0.074 0.055 0.053 0.010

Sugar 0.087 0.131 0.124 0.113 0.019

Western white 0.038 0.078 0.052 0.048 0.005

Redwood 0.089 0.087 0.066 0.077 0.011

Spruce, Sitka 0.043 0.078 0.064 0.061 0.003

Spruce, Engelmann 0.059 0.128 0.124 0.120 0.010

a

E

L

may be approximated by increasing modulus of elasticity values in

Table 5–3 by 10%.

General Technical Report FPL–GTR–190

5–3

Chapter 5 Mechanical Properties of Wood

Modulus of Rigidity

The modulus of rigidity, also called shear modulus, indi-

cates the resistance to deection of a member caused by

shear stresses. The three moduli of rigidity denoted by G

LR

,

G

LT

, and G

RT

are the elastic constants in the LR, LT, and

RT planes, respectively. For example, G

LR

is the modulus

of rigidity based on shear strain in the LR plane and shear

stresses in the LT and RT planes. Average values of shear

moduli for samples of a few species expressed as ratios with

E

L

are given in Table 5–1. As with moduli of elasticity, the

moduli of rigidity vary within and between species and

with moisture content and specic gravity.

Strength Properties

Common Properties

Mechanical properties most commonly measured and repre-

sented as “strength properties” for design include modulus

of rupture in bending, maximum stress in compression par-

allel to grain, compressive stress perpendicular to grain, and

shear strength parallel to grain. Additional measurements

are often made to evaluate work to maximum load in bend-

ing, impact bending strength, tensile strength perpendicular

to grain, and hardness. These properties, grouped according

to the broad forest tree categories of hardwood and soft-

wood (not correlated with hardness or softness), are given in

Tables 5–3 to 5–5 for many of the commercially important

species. Average coefcients of variation for these proper-

ties from a limited sampling of specimens are reported in

Table 5–6.

Modulus of rupture—Reects the maximum load-carrying

capacity of a member in bending and is proportional to max-

imum moment borne by the specimen. Modulus of rupture

is an accepted criterion of strength, although it is not a true

stress because the formula by which it is computed is valid

only to the elastic limit.

Work to maximum load in bending—Ability to absorb

shock with some permanent deformation and more or less

injury to a specimen. Work to maximum load is a measure

of the combined strength and toughness of wood under

bending stresses.

Compressive strength parallel to grain—Maximum stress

sustained by a compression parallel-to-grain specimen hav-

ing a ratio of length to least dimension of less than 11.

Compressive stress perpendicular to grain—Reported as

stress at proportional limit. There is no clearly dened ulti-

mate stress for this property.

Shear strength parallel to grain—Ability to resist internal

slipping of one part upon another along the grain. Values

presented are average strength in radial and tangential shear

planes.

Impact bending—In the impact bending test, a hammer of

given weight is dropped upon a beam from successively in-

creased heights until rupture occurs or the beam deects

152 mm (6 in.) or more. The height of the maximum drop,

or the drop that causes failure, is a comparative value that

represents the ability of wood to absorb shocks that cause

stresses beyond the proportional limit.

Tensile strength perpendicular to grain—Resistance of

wood to forces acting across the grain that tend to split a

member. Values presented are the average of radial and

tangential observations.

Hardness—Generally dened as resistance to indentation

using a modied Janka hardness test, measured by the load

required to embed a 11.28-mm (0.444-in.) ball to one-half

its diameter. Values presented are the average of radial and

tangential penetrations.

Tensile strength parallel to grain—Maximum tensile

stress sustained in direction parallel to grain. Relatively few

data are available on the tensile strength of various species

Table 5–2. Poisson’s ratios for various species at

approximately 12% moisture content

Species µ

LR

µ

LT

µ

RT

µ

TR

µ

RL

µ

TL

Hardwoods

Ash, white 0.371 0.440 0.684 0.360 0.059 0.051

Aspen, quaking 0.489 0.374 — 0.496 0.054 0.022

Balsa 0.229 0.488 0.665 0.231 0.018 0.009

Basswood 0.364 0.406 0.912 0.346 0.034 0.022

Birch, yellow 0.426 0.451 0.697 0.426 0.043 0.024

Cherry, black 0.392 0.428 0.695 0.282 0.086 0.048

Cottonwood, eastern 0.344 0.420 0.875 0.292 0.043 0.018

Mahogany, African 0.297 0.641 0.604 0.264 0.033 0.032

Mahogany, Honduras 0.314 0.533 0.600 0.326 0.033 0.034

Maple, sugar 0.424 0.476 0.774 0.349 0.065 0.037

Maple, red 0.434 0.509 0.762 0.354 0.063 0.044

Oak, red 0.350 0.448 0.560 0.292 0.064 0.033

Oak, white 0.369 0.428 0.618 0.300 0.074 0.036

Sweetgum 0.325 0.403 0.682 0.309 0.044 0.023

Walnut, black 0.495 0.632 0.718 0.367 0.052 0.036

Yellow-poplar 0.318 0.392 0.703 0.329 0.030 0.019

Softwoods

Baldcypress 0.338 0.326 0.411 0.356 — —

Cedar, northern white 0.337 0.340 0.458 0.345 — —

Cedar, western red 0.378 0.296 0.484 0.403 — —

Douglas-fir 0.292 0.449 0.390 0.374 0.036 0.029

Fir, subalpine 0.341 0.332 0.437 0.336 — —

Hemlock, western 0.485 0.423 0.442 0.382 — —

Larch, western 0.355 0.276 0.389 0.352 — —

Pine

Loblolly 0.328 0.292 0.382 0.362 — —

Lodgepole 0.316 0.347 0.469 0.381 — —

Longleaf 0.332 0.365 0.384 0.342 — —

Pond 0.280 0.364 0.389 0.320 — —

Ponderosa 0.337 0.400 0.426 0.359 — —

Red 0.347 0.315 0.408 0.308 — —

Slash 0.392 0.444 0.447 0.387 — —

Sugar 0.356 0.349 0.428 0.358 — —

Western white 0.329 0.344 0.410 0.334 — —

Redwood 0.360 0.346 0.373 0.400 — —

Spruce, Sitka 0.372 0.467 0.435 0.245 0.040 0.025

Spruce, Engelmann 0.422 0.462 0.530 0.255 0.083 0.058

5–4

Errata, 2018: Corrected MOR value for 12% MC white ash.

Table 5–3a. Strength properties of some commercially important woods grown in the United States (metric)

a

Static bending

Impact

bending

(mm)

Com-

pression

parallel

to grain

(kPa)

Com-

pression

perpen-

dicular

to grain

(kPa)

Shear

parallel

to

grain

(kPa)

Tension

perpen-

dicular

to grain

(kPa)

Side

hard-

ness

(N)

Modulus

of

rupture

(kPa)

Modulus

of

elasticity

c

(MPa)

Work to

maxi-

mum

load

(kJ m

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Hardwoods

Alder, red Green 0.37 45,000 8,100 55 560 20,400 1,700 5,300 2,700 2,000

12% 0.41 68,000 9,500 58 510 40,100 3,000 7,400 2,900 2,600

Ash

Black Green 0.45 41,000 7,200 83 840 15,900 2,400 5,900 3,400 2,300

12% 0.49 87,000 11,000 103 890 41,200 5,200 10,800 4,800 3,800

Blue Green 0.53 66,000 8,500 101 — 28,800 5,600 10,600 — —

12% 0.58 95,000 9,700 99 — 48,100 9,800 14,000 — —

Green Green 0.53 66,000 9,700 81 890 29,000 5,000 8,700 4,100 3,900

12% 0.56 97,000 11,400 92 810 48,800 9,000 13,200 4,800 5,300

Oregon Green 0.50 52,000 7,800 84 990 24,200 3,700 8,200 4,100 3,500

12% 0.55 88,000 9,400 99 840 41,600 8,600 12,300 5,000 5,200

White Green 0.55 66,000 9,900 108 970 27,500 4,600 9,300 4,100 4,300

12% 0.60

10

6,000 12,000 115 1,090 51,100 8,000 13,200 6,500 5,900

Aspen

Bigtooth Green 0.36 37,000 7,700 39 — 17,200 1,400 5,000 — —

12% 0.39 63,000 9,900 53 — 36,500 3,100 7,400 — —

Quaking Green 0.35 35,000 5,900 44 560 14,800 1,200 4,600 1,600 1,300

12% 0.38 58,000 8,100 52 530 29,300 2,600 5,900 1,800 1,600

Basswood, American Green 0.32 34,000 7,200 37 410 15,300 1,200 4,100 1,900 1,100

12% 0.37 60,000 10,100 50 410 32,600 2,600 6,800 2,400 1,800

Beech, American Green 0.56 59,000 9,500 82 1,090 24,500 3,700 8,900 5,000 3,800

12% 0.64 103,000 11,900 104 1,040 50,300 7,000 13,900 7,000 5,800

Birch

Paper Green 0.48 44,000 8,100 112 1,240 16,300 1,900 5,800 2,600 2,500

12% 0.55 85,000 11,000 110 860 39,200 4,100 8,300 — 4,000

Sweet Green 0.60 65,000 11,400 108 1,220 25,800 3,200 8,500 3,000 4,300

12% 0.65 117,000 15,000 124 1,190 58,900 7,400 15,400 6,600 6,500

Yellow Green 0.55 57,000 10,300 111 1,220 23,300 3,000 7,700 3,000 3,600

12% 0.62 114,000 13,900 143 1,400 56,300 6,700 13,000 6,300 5,600

Butternut Green 0.36 37,000 6,700 57 610 16,700 1,500 5,200 3,000 1,700

12% 0.38 56,000 8,100 57 610 36,200 3,200 8,100 3,000 2,200

Cherry, black Green 0.47 55,000 9,000 88 840 24,400 2,500 7,800 3,900 2,900

12% 0.50 85,000 10,300 79 740 49,000 4,800 11,700 3,900 4,200

Chestnut, American Green 0.40 39,000 6,400 48 610 17,000 2,100 5,500 3,000 1,900

12% 0.43 59,000 8,500 45 480 36,700 4,300 7,400 3,200 2,400

Cottonwood

Balsam poplar Green 0.31 27,000 5,200 29 — 11,700 1,000 3,400 — —

12% 0.34 47,000 7,600 34 — 27,700 2,100 5,400 — —

Black Green 0.31 34,000 7,400 34 510 15,200 1,100 4,200 1,900 1,100

12% 0.35 59,000 8,800 46 560 31,000 2,100 7,200 2,300 1,600

Eastern Green 0.37 37,000 7,000 50 530 15,700 1,400 4,700 2,800 1,500

12% 0.40 59,000 9,400 51 510 33,900 2,600 6,400 4,000 1,900

Elm

American Green 0.46 50,000 7,700 81 970 20,100 2,500 6,900 4,100 2,800

12% 0.50 81,000 9,200 90 990 38,100 4,800 10,400 4,600 3,700

Rock Green 0.57 66,000 8,200 137 1,370 26,100 4,200 8,800 — —

12% 0.63 102,000 10,600 132 1,420 48,600 8,500 13,200 — —

Slippery Green 0.48 55,000 8,500 106 1,190 22,900 2,900 7,700 4,400 2,900

12% 0.53 90,000 10,300 117 1,140 43,900 5,700 11,200 3,700 3,800

Hackberry Green 0.49 45,000 6,600 100 1,220 18,300 2,800 7,400 4,300 3,100

12% 0.53 76,000 8,200 88 1,090 37,500 6,100 11,000 4,000 3,900

General Technical Report FPL–GTR–190

5–5

Chapter 5 Mechanical Properties of Wood

Table 5–3a. Strength properties of some commercially important woods grown in the United States (metric)

a

—con.

Static bending

Impact

bending

(mm)

Com-

pression

parallel

to grain

(kPa)

Com-

pression

perpen-

dicular

to grain

(kPa)

Shear

parallel

to

grain

(kPa)

Tension

perpen-

dicular to

grain

(kPa)

Side

hard-

ness

(N)

Modulus

of

rupture

(kPa)

Modulus

of

elasticity

c

(MPa)

Work to

maxi-

mum

load

(kJ m

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Hickory, pecan

Bitternut Green 0.60 71,000 9,700 138 1,680 31,500 5,500 8,500 — —

12% 0.66 118,000 12,300 125 1,680 62,300 11,600 — — —

Nutmeg Green 0.56 63,000 8,900 157 1,370 27,400 5,200 7,100 — —

12% 0.60 114,000 11,700 173 — 47,600 10,800 — — —

Pecan Green 0.60 68,000 9,400 101 1,350 27,500 5,400 10,200 4,700 5,800

12% 0.66 94,000 11,900 95 1,120 54,100 11,900 14,300 — 8,100

Water Green 0.61 74,000 10,800 130 1,420 32,100 6,100 9,900 — —

12% 0.62 123,000 13,900 133 1,350 59,300 10,700 — — —

Hickory, true

d

Mockernut Green 0.64 77,000 10,800 180 2,240 30,900 5,600 8,800 — 6,400

12% 0.72 132,000 15,300 156 1,960 61,600 11,900 12,000 — 8,800

Pignut Green 0.66 81,000 11,400 219 2,260 33,200 6,300 9,400 — 6,800

12% 0.75 139,000 15,600 210 1,880 63,400 13,700 14,800 — 9,500

Shagbark Green 0.64 76,000 10,800 163 1,880 31,600 5,800 10,500 — 6,500

12% 0.72 139,000 14,900 178 1,700 63,500 12,100 16,800 — 8,400

Shellbark Green 0.62 72,000 9,200 206 2,640 27,000 5,600 8,200 — 7,400

12% 0.69 125,000 13,000 163 2,240 55,200 12,400 14,500 — 8,100

Honeylocust Green 0.60 70,000 8,900 87 1,190 30,500 7,900 11,400 6,400 6,200

12% — 101,000 11,200 92 1,190 51,700 12,700 15,500 6,200 7,000

Locust, black Green 0.66 95,000 12,800 106 1,120 46,900 8,000 12,100 5,300 7,000

12% 0.69 134,000 14,100 127 1,450 70,200 12,600 17,100 4,400 7,600

Magnolia

Cucumbertree Green 0.44 51,000 10,800 69 760 21,600 2,300 6,800 3,000 2,300

12% 0.48 85,000 12,500 84 890 43,500 3,900 9,200 4,600 3,100

Southern Green 0.46 47,000 7,700 106 1,370 18,600 3,200 7,200 4,200 3,300

12% 0.50 77,000 9,700 88 740 37,600 5,900 10,500 5,100 4,500

Maple

Bigleaf Green 0.44 51,000 7,600 60 580 22,300 3,100 7,700 4,100 2,800

12% 0.48 74,000 10,000 54 710 41,000 5,200 11,900 3,700 3,800

Black Green 0.52 54,000 9,200 88 1,220 22,500 4,100 7,800 5,000 3,700

12% 0.57 92,000 11,200 86 1,020 46,100 7,000 12,500 4,600 5,200

Red Green 0.49 53,000 9,600 79 810 22,600 2,800 7,900 — 3,100

12% 0.54 92,000 11,300 86 810 45,100 6,900 12,800 — 4,200

Silver Green 0.44 40,000 6,500 76 740 17,200 2,600 7,200 3,900 2,600

12% 0.47 61,000 7,900 57 640 36,000 5,100 10,200 3,400 3,100

Sugar Green 0.56 65,000 10,700 92 1,020 27,700 4,400 10,100 — 4,300

12% 0.63 109,000 12,600 114 990 54,000 10,100 16,100 — 6,400

Oak, red

Black Green 0.56 57,000 8,100 84 1,020 23,900 4,900 8,400 — 4,700

12% 0.61 96,000 11,300 94 1,040 45,000 6,400 13,200 — 5,400

Cherrybark Green 0.61 74,000 12,300 101 1,370 31,900 5,200 9,100 5,500 5,500

12% 0.68 125,000 15,700 126 1,240 60,300 8,600 13,800 5,800 6,600

Laurel Green 0.56 54,000 9,600 77 990 21,900 3,900 8,100 5,300 4,400

12% 0.63 87,000 11,700 81 990 48,100 7,300 12,600 5,400 5,400

Northern red Green 0.56 57,000 9,300 91 1,120 23,700 4,200 8,300 5,200 4,400

12% 0.63 99,000 12,500 100 1,090 46,600 7,000 12,300 5,500 5,700

Pin Green 0.58 57,000 9,100 97 1,220 25,400 5,000 8,900 5,500 4,800

12% 0.63 97,000 11,900 102 1,140 47,000 7,000 14,300 7,200 6,700

Scarlet Green 0.60 72,000 10,200 103 1,370 28,200 5,700 9,700 4,800 5,300

12% 0.67 120,000 13,200 141 1,350 57,400 7,700 13,000 6,000 6,200

Southern red Green 0.52 48,000 7,900 55 740 20,900 3,800 6,400 3,300 3,800

12% 0.59 75,000 10,300 65 660 42,000 6,000 9,600 3,500 4,700

Water Green 0.56 61,000 10,700 77 990 25,800 4,300 8,500 5,700 4,500

12% 0.63 106,000 13,900 148 1,120 46,700 7,000 13,900 6,300 5,300

5–6

Table 5–3a. Strength properties of some commercially important woods grown in the United States (metric)

a

—con.

Static bending

Impact

bending

(mm)

Com-

pression

parallel

to grain

(kPa)

Com-

pression

perpen-

dicular

to grain

(kPa)

Tension

perpen-

dicular

to grain

(kPa)

Side

hard-

ness

(N)

Modulus

of

rupture

(kPa)

Modulus

of

elasticity

c

(MPa)

Work to

maxi-

mum

load

(kJ m

–3

)

Shear

parallel

to

grain

(kPa)

Common species

names

Moisture

content

Specific

gravity

b

Oak, red—con.

Willow Green 0.56 51,000 8,900 61 890 20,700 4,200 8,100 5,200 4,400

12% 0.69 100,000 13,100 101 1,070 48,500 7,800 11,400 — 6,500

Oak, white

Bur Green 0.58 50,000 6,100 74 1,120 22,700 4,700 9,300 5,500 4,900

12% 0.64 71,000 7,100 68 740 41,800 8,300 12,500 4,700 6,100

Chestnut Green 0.57 55,000 9,400 65 890 24,300 3,700 8,300 4,800 4,000

12% 0.66 92,000 11,000 76 1,020 47,100 5,800 10,300 — 5,000

Live Green 0.80 82,000 10,900 85 — 37,400 14,100 15,200 — —

12% 0.88 127,000 13,700 130 — 61,400 19,600 18,300 — —

Overcup Green 0.57 55,000 7,900 87 1,120 23,200 3,700 9,100 5,000 4,300

12% 0.63 87,000 9,800 108 970 42,700 5,600 13,800 6,500 5,300

Post Green 0.60 56,000 7,500 76 1,120 24,000 5,900 8,800 5,400 5,000

12% 0.67 91,000 10,400 91 1,170 45,300 9,900 12,700 5,400 6,000

Swamp chestnut Green 0.60 59,000 9,300 88 1,140 24,400 3,900 8,700 4,600 4,900

12% 0.67 96,000 12,200 83 1,040 50,100 7,700 13,700 4,800 5,500

Swamp white Green 0.64 68,000 11,000 100 1,270 30,100 5,200 9,000 5,900 5,200

12% 0.72 122,000 14,100 132 1,240 59,300 8,200 13,800 5,700 7,200

White Green 0.60 57,000 8,600 80 1,070 24,500 4,600 8,600 5,300 4,700

12% 0.68 105,000 12,300 102 940 51,300 7,400 13,800 5,500 6,000

Sassafras Green 0.42 41,000 6,300 49 — 18,800 2,600 6,600 — —

12% 0.46 62,000 7,700 60 — 32,800 5,900 8,500 — —

Sweetgum Green 0.46 49,000 8,300 70 910 21,000 2,600 6,800 3,700 2,700

12% 0.52 86,000 11,300 82 810 43,600 4,300 11,000 5,200 3,800

Sycamore, American Green 0.46 45,000 7,300 52 660 20,100 2,500 6,900 4,300 2,700

12% 0.49 69,000 9,800 59 660 37,100 4,800 10,100 5,000 3,400

Tanoak Green 0.58 72,000 10,700 92 — 32,100 — — — —

12% — — — — — — — — — —

Tupelo

Black Green 0.46 48,000 7,100 55 760 21,000 3,300 7,600 3,900 2,800

12% 0.50 66,000 8,300 43 560 38,100 6,400 9,200 3,400 3,600

Water Green 0.46 50,000 7,200 57 760 23,200 3,300 8,200 4,100 3,200

12% 0.50 66,000 8,700 48 580 40,800 6,000 11,000 4,800 3,900

Walnut, black Green 0.51 66,000 9,800 101 940 29,600 3,400 8,400 3,900 4,000

12% 0.55 101,000 11,600 74 860 52,300 7,000 9,400 4,800 4,500

Willow, black Green 0.36 33,000 5,400 76 — 14,100 1,200 4,700 — —

12% 0.39 54,000 7,000 61 — 28,300 3,000 8,600 — —

Yellow-poplar Green 0.40 41,000 8,400 52 660 18,300 1,900 5,400 3,500 2,000

12% 0.42 70,000 10,900 61 610 38,200 3,400 8,200 3,700 2,400

Softwoods

Baldcypress Green 0.42 46,000 8,100 46 640 24,700 2,800 5,600 2,100 1,700

12% 0.46 73,000 9,900 57 610 43,900 5,000 6,900 1,900 2,300

Cedar

Atlantic white Green 0.31 32,000 5,200 41 460 16,500 1,700 4,800 1,200 1,300

12% 0.32 47,000 6,400 28 330 32,400 2,800 5,500 1,500 1,600

Eastern redcedar Green 0.44 48,000 4,500 103 890 24,600 4,800 7,000 2,300 2,900

12% 0.47 61,000 6,100 57 560 41,500 6,300 — — 4,000

Incense Green 0.35 43,000 5,800 44 430 21,700 2,600 5,700 1,900 1,700

12% 0.37 55,000 7,200 37 430 35,900 4,100 6,100 1,900 2,100

Northern white Green 0.29 29,000 4,400 39 380 13,700 1,600 4,300 1,700 1,000

12% 0.31 45,000 5,500 33 300 27,300 2,100 5,900 1,700 1,400

General Technical Report FPL–GTR–190

Chapter 5 Mechanical Properties of Wood

5–7

Table 5–3a. Strength properties of some commercially important woods grown in the United States (metric)

a

—con.

Static bending

Impact

bending

(mm)

Com-

pression

parallel

to grain

(kPa)

Com-

pression

perpen-

dicular

to grain

(kPa)

Shear

parallel

to

grain

(kPa)

Tension

perpen-

dicular

to grain

(kPa)

Side

hard-

ness

(N)

Modulus

of

rupture

(kPa)

Modulus

of

elasticity

c

(MPa)

Work to

maxi-

mum

load

(kJ m

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Cedar—con.

Port-Orford Green 0.39 45,000 9,000 51 530 21,600 2,100 5,800 1,200 1,700

12% 0.43 88,000 11,700 63 710 43,100 5,000 9,400 2,800 2,800

Western redcedar Green 0.31 35,900 6,500 34 430 19,100 1,700 5,300 1,600 1,200

12% 0.32 51,700 7,700 40 430 31,400 3,200 6,800 1,500 1,600

Yellow Green 0.42 44,000 7,900 63 690 21,000 2,400 5,800 2,300 2,000

12% 0.44 77,000 9,800 72 740 43,500 4,300 7,800 2,500 2,600

Douglas-fir

e

Coast Green 0.45 53,000 10,800 52 660 26,100 2,600 6,200 2,100 2,200

12% 0.48 85,000 13,400 68 790 49,900 5,500 7,800 2,300 3,200

Interior West Green 0.46 53,000 10,400 50 660 26,700 2,900 6,500 2,000 2,300

12% 0.50 87,000 12,600 73 810 51,200 5,200 8,900 2,400 2,900

Interior North Green 0.45 51,000 9,700 56 560 23,900 2,500 6,600 2,300 1,900

12% 0.48 90,000 12,300 72 660 47,600 5,300 9,700 2,700 2,700

Interior South Green 0.43 47,000 8,000 55 380 21,400 2,300 6,600 1,700 1,600

12% 0.46 82,000 10,300 62 510 43,000 5,100 10,400 2,300 2,300

Fir

Balsam Green 0.33 38,000 8,600 32 410 18,100 1,300 4,600 1,200 1,300

12% 0.35 63,000 10,000 35 510 36,400 2,800 6,500 1,200 1,700

California red Green 0.36 40,000 8,100 44 530 19,000 2,300 5,300 2,600 1,600

12% 0.38 72,400 10,300 61 610 37,600 4,200 7,200 2,700 2,200

Grand Green 0.35 40,000 8,600 39 560 20,300 1,900 5,100 1,700 1,600

12% 0.37 61,400 10,800 52 710 36,500 3,400 6,200 1,700 2,200

Noble Green 0.37 43,000 9,500 41 480 20,800 1,900 5,500 1,600 1,300

12% 0.39 74,000 11,900 61 580 42,100 3,600 7,200 1,500 1,800

Pacific silver Green 0.40 44,000 9,800 41 530 21,600 1,500 5,200 1,700 1,400

12% 0.43 75,800 12,100 64 610 44,200 3,100 8,400 — 1,900

Subalpine Green 0.31 34,000 7,200 — — 15,900 1,300 4,800 — 1,200

12% 0.32 59,000 8,900 — — 33,500 2,700 7,400 — 1,600

White Green 0.37 41,000 8,000 39 560 20,000 1,900 5,200 2,100 1,500

12% 0.39 68,000 10,300 50 510 40,000 3,700 7,600 2,100 2,100

Hemlock

Eastern Green 0.38 44,000 7,400 46 530 21,200 2,500 5,900 1,600 1,800

12% 0.40 61,000 8,300 47 530 37,300 4,500 7,300 — 2,200

Mountain Green 0.42 43,000 7,200 76 810 19,900 2,600 6,400 2,300 2,100

12% 0.45 79,000 9,200 72 810 44,400 5,900 10,600 — 3,000

Western Green 0.42 46,000 9,000 48 560 23,200 1,900 5,900 2,000 1,800

12% 0.45 78,000 11,300 57 580 49,000 3,800 8,600 2,300 2,400

Larch, western Green 0.48 53,000 10,100 71 740 25,900 2,800 6,000 2,300 2,300

12% 0.52 90,000 12,900 87 890 52,500 6,400 9,400 3,000 3,700

Pine

Eastern white Green 0.34 34,000 6,800 36 430 16,800 1,500 4,700 1,700 1,300

12% 0.35 59,000 8,500 47 460 33,100 3,000 6,200 2,100 1,700

Jack Green 0.40 41,000 7,400 50 660 20,300 2,100 5,200 2,500 1,800

12% 0.43 68,000 9,300 57 690 39,000 4,000 8,100 2,900 2,500

Loblolly Green 0.47 50,000 9,700 57 760 24,200 2,700 5,900 1,800 2,000

12% 0.51 88,000 12,300 72 760 49,200 5,400 9,600 3,200 3,100

Lodgepole Green 0.38 38,000 7,400 39 510 18,000 1,700 4,700 1,500 1,500

12% 0.41 65,000 9,200 47 510 37,000 4,200 6,100 2,000 2,100

Longleaf Green 0.54 59,000 11,000 61 890 29,800 3,300 7,200 2,300 2,600

12% 0.59 100,000 13,700 81 860 58,400 6,600 10,400 3,200 3,900

Pitch Green 0.47 47,000 8,300 63 — 20,300 2,500 5,900 — —

12% 0.52 74,000 9,900 63 — 41,000 5,600 9,400 — —

5–8

Table 5–3a. Strength properties of some commercially important woods grown in the United States (metric)

a

—con.

Static bending

Impact

bending

(mm)

Com-

pression

parallel

to grain

(kPa)

Com-

pression

perpen-

icular

to grain

(kPa)

Tension

perpen-

dicular

to grain

(kPa)

Side

hard-

ness

(N)

Modulus

of

rupture

(kPa)

Modulus

of

elasticity

c

(MPa)

Work to

maxi-

mum

load

(kJ m

–3

)

Shear

parallel

to

grain

(kPa)

Common species

names

Moisture

content

Specific

gravity

b

Pine—con.

Pond Green 0.51 51,000 8,800 52 — 25,200 3,000 6,500 — —

12% 0.56 80,000 12,100 59 — 52,000 6,300 9,500 — —

Ponderosa Green 0.38 35,000 6,900 36 530 16,900 1,900 4,800 2,100 1,400

12% 0.40 65,000 8,900 49 480 36,700 4,000 7,800 2,900 2,000

Red Green 0.41 40,000 8,800 42 660 18,800 1,800 4,800 2,100 1,500

12% 0.46 76,000 11,200 68 660 41,900 4,100 8,400 3,200 2,500

Sand Green 0.46 52,000 7,000 66 — 23,700 3,100 7,900 — —

12% 0.48 80,000 9,700 66 — 47,700 5,800 — — —

Shortleaf Green 0.47 51,000 9,600 57 760 24,300 2,400 6,300 2,200 2,000

12% 0.51 90,000 12,100 76 840 50,100 5,700 9,600 3,200 3,100

Slash Green 0.54 60,000 10,500 66 — 26,300 3,700 6,600 — —

12% 0.59 112,000 13,700 91 — 56,100 7,000 11,600 — —

Spruce Green 0.41 41,000 6,900 — — 19,600 1,900 6,200 — 2,000

12% 0.44 72,000 8,500 — — 39,000 5,000 10,300 — 2,900

Sugar Green 0.34 34,000 7,100 37 430 17,000 1,400 5,000 1,900 1,200

12% 0.36 57,000 8,200 38 460 30,800 3,400 7,800 2,400 1,700

Virginia Green 0.45 50,000 8,400 75 860 23,600 2,700 6,100 2,800 2,400

12% 0.48 90,000 10,500 94 810 46,300 6,300 9,300 2,600 3,300

Western white Green 0.36 32,000 8,200 34 480 16,800 1,300 4,700 1,800 1,200

12% 0.35 67,000 10,100 61 580 34,700 3,200 7,200 — 1,900

Redwood

Old-growth Green 0.38 52,000 8,100 51 530 29,000 2,900 5,500 1,800 1,800

12% 0.40 69,000 9,200 48 480 42,400 4,800 6,500 1,700 2,100

Young-growth Green 0.34 41,000 6,600 39 410 21,400 1,900 6,100 2,100 1,600

12% 0.35 54,000 7,600 36 380 36,000 3,600 7,600 1,700 1,900

Spruce

Black Green 0.38 42,000 9,500 51 610 19,600 1,700 5,100 700 1,500

12% 0.42 74,000 11,100 72 580 41,100 3,800 8,500 — 2,400

Engelmann Green 0.33 32,000 7,100 35 410 15,000 1,400 4,400 1,700 1,150

12% 0.35 64,000 8,900 44 460 30,900 2,800 8,300 2,400 1,750

Red Green 0.37 41,000 9,200 48 460 18,800 1,800 5,200 1,500 1,600

12% 0.40 74,000 11,400 58 640 38,200 3,800 8,900 2,400 2,200

Sitka Green 0.37 39,000 8,500 43 610 18,400 1,900 5,200 1,700 1,600

12% 0.40 70,000 10,800 65 640 38,700 4,000 7,900 2,600 2,300

White Green 0.33 34,000 7,900 41 560 16,200 1,400 4,400 1,500 1,200

12% 0.36 65,000 9,600 53 510 35,700 3,000 6,700 2,500 1,800

Tamarack Green 0.49 50,000 8,500 50 710 24,000 2,700 5,900 1,800 1,700

12% 0.53 80,000 11,300 49 580 49,400 5,500 8,800 2,800 2,600

a

Results of tests on clear specimens in the green and air-dried conditions, converted to metric units directly from Table 5–3b. Definition of properties:

impact bending is height of drop that causes complete failure, using 0.71-kg (50-lb) hammer; compression parallel to grain is also called maximum

crushing strength; compression perpendicular to grain is fiber stress at proportional limit; shear is maximum shearing strength; tension is maximum tensile

strength; and side hardness is hardness measured when load is perpendicular to grain.

b

Specific gravity is based on weight when ovendry and volume when green or at 12% moisture content.

c

Modulus of elasticity measured from a simply supported, center-loaded beam, on a span depth ratio of 14/1. To correct for shear deflection, the modulus

can be increased by 10%.

d

Values for side hardness of the true hickories are from Bendtsen and Ethington (1975).

e

Coast Douglas-fir is defined as Douglas-fir growing in Oregon and Washington State west of the Cascade Mountains summit. Interior West includes

California and all counties in Oregon and Washington east of, but adjacent to, the Cascade summit; Interior North, the remainder of Oregon and

Washington plus Idaho, Montana, and Wyoming; and Interior South, Utah, Colorado, Arizona, and New Mexico.

General Technical Report FPL–GTR–190

Chapter 5 Mechanical Properties of Wood

Errata, 2018: Corrected MOR value for 12% MC white ash. 5–9

Table 5–3b. Strength properties of some commercially important woods grown in the United States (inch–pound)

a

Static bending

Impact

bending

(in.)

Com-

pression

parallel

to grain

(lbf in

–2

)

Com-

pression

perpen-

dicular

to grain

(lbf in

–2

)

Side

hard-

ness

(lbf)

Modulus

of

rupture

(lbf in

–2

)

Modulus

of

elasticity

c

(10

6

lbf in

–2

)

Work

to

maxi-

mum

load

(in-lbf in

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Shear

parallel

to

grain

(lbf in

–2

)

Tension

perpen-

dicular

to grain

(lbf in

–2

)

Hardwoods

Alder, red Green 0.37 6,500 1.17 8.0 22 2,960 250 770 390 440

12% 0.41 9,800 1.38 8.4 20 5,820 440 1,080 420 590

Ash

Black Green 0.45 6,000 1.04 12.1 33 2,300 350 860 490 520

12% 0.49 12,600 1.60 14.9 35 5,970 760 1,570 700 850

Blue Green 0.53 9,600 1.24 14.7 — 4,180 810 1,540 — —

12% 0.58 13,800 1.40 14.4 — 6,980 1,420 2,030 — —

Green Green 0.53 9,500 1.40 11.8 35 4,200 730 1,260 590 870

12% 0.56 14,100 1.66 13.4 32 7,080 1,310 1,910 700 1,200

Oregon Green 0.50 7,600 1.13 12.2 39 3,510 530 1,190 590 790

12% 0.55 12,700 1.36 14.4 33 6,040 1,250 1,790 720 1,160

White Green 0.55 9,500 1.44 15.7 38 3,990 670 1,350 590 960

12% 0.60

15,

400 1.74 16.6 43 7,410 1,160 1,910 940 1,320

Aspen

Bigtooth Green 0.36 5,400 1.12 5.7 — 2,500 210 730 — —

12% 0.39 9,100 1.43 7.7 — 5,300 450 1,080 — —

Quaking Green 0.35 5,100 0.86 6.4 22 2,140 180 660 230 300

12% 0.38 8,400 1.18 7.6 21 4,250 370 850 260 350

Basswood, American Green 0.32 5,000 1.04 5.3 16 2,220 170 600 280 250

12% 0.37 8,700 1.46 7.2 16 4,730 370 990 350 410

Beech, American Green 0.56 8,600 1.38 11.9 43 3,550 540 1,290 720 850

12% 0.64 14,900 1.72 15.1 41 7,300 1,010 2,010 1,010 1,300

Birch

Paper Green 0.48 6,400 1.17 16.2 49 2,360 270 840 380 560

12% 0.55 12,300 1.59 16.0 34 5,690 600 1,210 — 910

Sweet Green 0.60 9,400 1.65 15.7 48 3,740 470 1,240 430 970

12% 0.65 16,900 2.17 18.0 47 8,540 1,080 2,240 950 1,470

Yellow Green 0.55 8,300 1.50 16.1 48 3,380 430 1,110 430 780

12% 0.62 16,600 2.01 20.8 55 8,170 970 1,880 920 1,260

Butternut Green 0.36 5,400 0.97 8.2 24 2,420 220 760 430 390

12% 0.38 8,100 1.18 8.2 24 5,110 460 1,170 440 490

Cherry, black Green 0.47 8,000 1.31 12.8 33 3,540 360 1,130 570 660

12% 0.50 12,300 1.49 11.4 29 7,110 690 1,700 560 950

Chestnut, American Green 0.40 5,600 0.93 7.0 24 2,470 310 800 440 420

12% 0.43 8,600 1.23 6.5 19 5,320 620 1,080 460 540

Cottonwood

Balsam, poplar Green 0.31 3,900 0.75 4.2 — 1,690 140 500 — —

12% 0.34 6,800 1.10 5.0 — 4,020 300 790 — —

Black Green 0.31 4,900 1.08 5.0 20 2,200 160 610 270 250

12% 0.35 8,500 1.27 6.7 22 4,500 300 1,040 330 350

Eastern Green 0.37 5,300 1.01 7.3 21 2,280 200 680 410 340

12% 0.40 8,500 1.37 7.4 20 4,910 380 930 580 430

Elm

American Green 0.46 7,200 1.11 11.8 38 2,910 360 1,000 590 620

12% 0.50 11,800 1.34 13.0 39 5,520 690 1,510 660 830

Rock Green 0.57 9,500 1.19 19.8 54 3,780 610 1,270 — 940

12% 0.63 14,800 1.54 19.2 56 7,050 1,230 1,920 — 1,320

Slippery Green 0.48 8,000 1.23 15.4 47 3,320 420 1,110 640 660

12% 0.53 13,000 1.49 16.9 45 6,360 820 1,630 530 860

Hackberry Green 0.49 6,500 0.95 14.5 48 2,650 400 1,070 630 700

12% 0.53 11,000 1.19 12.8 43 5,440 890 1,590 580 880

5–10

Table 5–3b. Strength properties of some commercially important woods grown in the United States (inch–pound)

a

—con.

Static bending

Impact

bending

(in.)

Com-

pression

parallel

to grain

(lbf in

–2

)

Com-

pression

perpen-

dicular

to grain

(lbf in

–2

)

Shear

parallel

to

grain

(lbf in

–2

)

Tension

perpen-

dicular

to grain

(lbf in

–2

)

Side

hard-

ness

(lbf)

Modulus

of

rupture

(lbf in

–2

)

Modulus

of

elasticity

c

(10

6

lbf in

–2

)

Work

to

maxi-

mum

load

(in-lbf in

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Hickory, pecan

Bitternut Green 0.60 10,300 1.40 20.0 66 4,570 800 1,240 — —

12% 0.66 17,100 1.79 18.2 66 9,040 1,680 — — —

Nutmeg Green 0.56 9,100 1.29 22.8 54 3,980 760 1,030 — —

12% 0.60 16,600 1.70 25.1 — 6,910 1,570 — — —

Pecan Green 0.60 9,800 1.37 14.6 53 3,990 780 1,480 680 1,31

0

12% 0.66 13,700 1.73 13.8 44 7,850 1,720 2,080 — 1,82

0

Water Green 0.61 10,700 1.56 18.8 56 4,660 880 1,440 — —

12% 0.62 17,800 2.02 19.3 53 8,600 1,550 — — —

Hickory, true

d

Mockernut Green 0.64 11,100 1.57 26.1 88 4,480 810 1,280 — 1,440

12% 0.72 19,200 2.22 22.6 77 8,940 1,730 1,740 — 1,970

Pignut Green 0.66 11,700 1.65 31.7 89 4,810 920 1,370 — 1,520

12% 0.75 20,100 2.26 30.4 74 9,190 1,980 2,150 — 2,140

Shagbark Green 0.64 11,000 1.57 23.7 74 4,580 840 1,520 — 1,460

12% 0.72 20,200 2.16 25.8 67 9,210 1,760 2,430 — 1,880

Shellbark Green 0.62 10,500 1.34 29.9 104 3,920 810 1,190 — 1,670

12% 0.69 18,100 1.89 23.6 88 8,000 1,800 2,110 — 1,810

Honeylocust Green 0.60 10,200 1.29 12.6 47 4,420 1,150 1,660 930 1,39

0

12% — 14,700 1.63 13.3 47 7,500 1,840 2,250 900 1,58

0

Locust, black Green 0.66 13,800 1.85 15.4 44 6,800 1,160 1,760 770 1,57

0

12% 0.69 19,400 2.05 18.4 57 10,180 1,830 2,480 640 1,70

0

Magnolia

Cucumbertree Green 0.44 7,400 1.56 10.0 30 3,140 330 990 440 52

0

12% 0.48 12,300 1.82 12.2 35 6,310 570 1,340 660 70

0

Southern Green 0.46 6,800 1.11 15.4 54 2,700 460 1,040 610 74

0

12% 0.50 11,200 1.40 12.8 29 5,460 860 1,530 740 1,02

0

Maple

Bigleaf Green 0.44 7,400 1.10 8.7 23 3,240 450 1,110 600 62

0

12% 0.48 10,700 1.45 7.8 28 5,950 750 1,730 540 85

0

Black Green 0.52 7,900 1.33 12.8 48 3,270 600 1,130 720 84

0

12% 0.57 13,300 1.62 12.5 40 6,680 1,020 1,820 670 1,18

0

Red Green 0.49 7,700 1.39 11.4 32 3,280 400 1,150 — 70

0

12% 0.54 13,400 1.64 12.5 32 6,540 1,000 1,850 — 95

0

Silver Green 0.44 5,800 0.94 11.0 29 2,490 370 1,050 560 59

0

12% 0.47 8,900 1.14 8.3 25 5,220 740 1,480 500 70

0

Sugar Green 0.56 9,400 1.55 13.3 40 4,020 640 1,460 — 97

0

12% 0.63 15,800 1.83 16.5 39 7,830 1,470 2,330 — 1,45

0

Oak, red

Black Green 0.56 8,200 1.18 12.2 40 3,470 710 1,220 — 1,06

0

12% 0.61 13,900 1.64 13.7 41 6,520 930 1,910 — 1,21

0

Cherrybark Green 0.61 10,800 1.79 14.7 54 4,620 760 1,320 800 1,24

0

12% 0.68 18,100 2.28 18.3 49 8,740 1,250 2,000 840 1,48

0

Laurel Green 0.56 7,900 1.39 11.2 39 3,170 570 1,180 770 1,00

0

12% 0.63 12,600 1.69 11.8 39 6,980 1,060 1,830 790 1,21

0

Northern red Green 0.56 8,300 1.35 13.2 44 3,440 610 1,210 750 1,00

0

12% 0.63 14,300 1.82 14.5 43 6,760 1,010 1,780 800 1,29

0

Pin Green 0.58 8,300 1.32 14.0 48 3,680 720 1,290 800 1,07

0

12% 0.63 14,000 1.73 14.8 45 6,820 1,020 2,080 1,050 1,51

0

Scarlet Green 0.60 10,400 1.48 15.0 54 4,090 830 1,410 700 1,20

0

12% 0.67 17,400 1.91 20.5 53 8,330 1,120 1,890 870 1,40

0

Southern red Green 0.52 6,900 1.14 8.0 29 3,030 550 930 480 86

0

12% 0.59 10,900 1.49 9.4 26 6,090 870 1,390 510 1,06

0

General Technical Report FPL–GTR–190

Chapter 5 Mechanical Properties of Wood

5–11

Table 5–3b. Strength properties of some commercially important woods grown in the United States (inch–pound)

a

—con.

Static bending

Impact

bending

(in.)

Com-

pression

parallel

to grain

(lbf in

–2

)

Com-

pression

perpen-

dicular

to grain

(lbf in

–2

)

Shear

parallel

to

grain

(lbf in

–2

)

Tension

perpen-

dicular

to grain

(lbf in

–2

)

Side

hard-

ness

(lbf)

Modulus

of

rupture

(lbf in

–2

)

Modulus

of

elasticity

c

(10

6

lbf in

–2

)

Work

to

maxi-

mum

load

(in-lbf in

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Oak, red—con.

Water Green 0.56 8,900 1.55 11.1 39 3,740 620 1,240 820 1,010

12% 0.63 15,400 2.02 21.5 44 6,770 1,020 2,020 920 1,190

Willow Green 0.56 7,400 1.29 8.8 35 3,000 610 1,180 760 980

12% 0.69 14,500 1.90 14.6 42 7,040 1,130 1,650 — 1,460

Oak, white

Bur Green 0.58 7,200 0.88 10.7 44 3,290 680 1,350 800 1,110

12% 0.64 10,300 1.03 9.8 29 6,060 1,200 1,820 680 1,370

Chestnut Green 0.57 8,000 1.37 9.4 35 3,520 530 1,210 690 890

12% 0.66 13,300 1.59 11.0 40 6,830 840 1,490 — 1,130

Live Green 0.80 11,900 1.58 12.3 — 5,430 2,040 2,210 — —

12% 0.88 18,400 1.98 18.9 — 8,900 2,840 2,660 — —

Overcup Green 0.57 8,000 1.15 12.6 44 3,370 540 1,320 730 960

12% 0.63 12,600 1.42 15.7 38 6,200 810 2,000 940 1,190

Post Green 0.60 8,100 1.09 11.0 44 3,480 860 1,280 790 1,130

12% 0.67 13,200 1.51 13.2 46 6,600 1,430 1,840 780 1,360

Swamp chestnut Green 0.60 8,500 1.35 12.8 45 3,540 570 1,260 670 1,110

12% 0.67 13,900 1.77 12.0 41 7,270 1,110 1,990 690 1,240

Swamp white Green 0.64 9,900 1.59 14.5 50 4,360 760 1,300 860 1,160

12% 0.72 17,700 2.05 19.2 49 8,600 1,190 2,000 830 1,620

White Green 0.60 8,300 1.25 11.6 42 3,560 670 1,250 770 1,060

12% 0.68 15,200 1.78 14.8 37 7,440 1,070 2,000 800 1,360

Sassafras Green 0.42 6,000 0.91 7.1 — 2,730 370 950 — —

12% 0.46 9,000 1.12 8.7 — 4,760 850 1,240 — —

Sweetgum Green 0.46 7,100 1.20 10.1 36 3,040 370 990 540 600

12% 0.52 12,500 1.64 11.9 32 6,320 620 1,600 760 850

Sycamore, American Green 0.46 6,500 1.06 7.5 26 2,920 360 1,000 630 610

12% 0.49 10,000 1.42 8.5 26 5,380 700 1,470 720 770

Tanoak Green 0.58 10,500 1.55 13.4 — 4,650 — — — —

12% — — — — — — — — — —

Tupelo

Black Green 0.46 7,000 1.03 8.0 30 3,040 480 1,100 570 640

12% 0.50 9,600 1.20 6.2 22 5,520 930 1,340 500 810

Water Green 0.46 7,300 1.05 8.3 30 3,370 480 1,190 600 710

12% 0.50 9,600 1.26 6.9 23 5,920 870 1,590 700 880

Walnut, Black Green 0.51 9,500 1.42 14.6 37 4,300 490 1,220 570 900

12% 0.55 14,600 1.68 10.7 34 7,580 1,010 1,370 690 1,010

Willow, Black Green 0.36 4,800 0.79 11.0 — 2,040 180 680 — —

12% 0.39 7,800 1.01 8.8 — 4,100 430 1,250 — —

Yellow-poplar Green 0.40 6,000 1.22 7.5 26 2,660 270 790 510 440

12% 0.42 10,100 1.58 8.8 24 5,540 500 1,190 540 540

Softwoods

Baldcypress Green 0.42 6,600 1.18 6.6 25 3,580 400 810 300 390

12% 0.46 10,600 1.44 8.2 24 6,360 730 1,000 270 510

Cedar

Atlantic white Green 0.31 4,700 0.75 5.9 18 2,390 240 690 180 290

12% 0.32 6,800 0.93 4.1 13 4,700 410 800 220 350

Eastern redcedar Green 0.44 7,000 0.65 15.0 35 3,570 700 1,010 330 650

12% 0.47 8,800 0.88 8.3 22 6,020 920 — — —

Incense Green 0.35 6,200 0.84 6.4 17 3,150 370 830 280 390

12% 0.37 8,000 1.04 5.4 17 5,200 590 880 270 470

Northern White Green 0.29 4,200 0.64 5.7 15 1,990 230 620 240 230

12% 0.31 6,500 0.80 4.8 12 3,960 310 850 240 320

5–12

Table 5–3b. Strength properties of some commercially important woods grown in the United States (inch–pound)

a

—con.

Static bending

Impact

bending

(in.)

Com-

pression

parallel

to grain

(lbf in

–2

)

Com-

pression

perpen-

dicular

to grain

(lbf in

–2

)

Shear

parallel

to

grain

(lbf in

–2

)

Tension

perpen-

dicular

to grain

(lbf in

–2

)

Side

hard-

ness

(lbf)

Modulus

of

rupture

(lbf in

–2

)

Modulus

of

elasticity

c

(10

6

lbf in

–2

)

Work

to

maxi-

mum

load

(in-lbf in

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Cedar—con.

Port-Orford Green 0.39 6,600 1.30 7.4 21 3,140 300 840 180 380

12% 0.43 12,700 1.70 9.1 28 6,250 720 1,370 400 630

Western redcedar Green 0.31 5,200 0.94 5.0 17 2,770 240 770 230 260

12% 0.32 7,500 1.11 5.8 17 4,560 460 990 220 350

Yellow Green 0.42 6,400 1.14 9.2 27 3,050 350 840 330 440

12% 0.44 11,100 1.42 10.4 29 6,310 620 1,130 360 580

Douglas-fir

e

Coast Green 0.45 7,700 1.56 7.6 26 3,780 380 900 300 500

12% 0.48 12,400 1.95 9.9 31 7,230 800 1,130 340 710

Interior West Green 0.46 7,700 1.51 7.2 26 3,870 420 940 290 510

12% 0.50 12,600 1.83 10.6 32 7,430 760 1,290 350 660

Interior North Green 0.45 7,400 1.41 8.1 22 3,470 360 950 340 420

12% 0.48 13,100 1.79 10.5 26 6,900 770 1,400 390 600

Interior South Green 0.43 6,800 1.16 8.0 15 3,110 340 950 250 360

12% 0.46 11,900 1.49 9.0 20 6,230 740 1,510 330 510

Fir

Balsam Green 0.33 5,500 1.25 4.7 16 2,630 190 660 180 290

12% 0.35 9,200 1.45 5.1 20 5,280 400 940 180 380

California red Green 0.36 5,800 1.17 6.4 21 2,760 330 770 380 360

12% 0.38 10,500 1.50 8.9 24 5,460 610 1,040 390 500

Grand Green 0.35 5,800 1.25 5.6 22 2,940 270 740 240 360

12% 0.37 8,900 1.57 7.5 28 5,290 500 900 240 490

Noble Green 0.37 6,200 1.38 6.0 19 3,010 270 800 230 290

12% 0.39 10,700 1.72 8.8 23 6,100 520 1,050 220 410

Pacific silver Green 0.40 6,400 1.42 6.0 21 3,140 220 750 240 310

12% 0.43 11,000 1.76 9.3 24 6,410 450 1,220 — 430

Subalpine Green 0.31 4,900 1.05 — — 2,300 190 700 — 260

12% 0.32 8,600 1.29 — — 4,860 390 1,070 — 350

White Green 0.37 5,900 1.16 5.6 22 2,900 280 760 300 340

12% 0.39 9,800 1.50 7.2 20 5,800 530 1,100 300 480

Hemlock

Eastern Green 0.38 6,400 1.07 6.7 21 3,080 360 850 230 400

12% 0.40 8,900 1.20 6.8 21 5,410 650 1,060 — 500

Mountain Green 0.42 6,300 1.04 11.0 32 2,880 370 930 330 470

12% 0.45 11,500 1.33 10.4 32 6,440 860 1,540 — 680

Western Green 0.42 6,600 1.31 6.9 22 3,360 280 860 290 410

12% 0.45 11,300 1.63 8.3 23 7,200 550 1,290 340 540

Larch, western Green 0.48 7,700 1.46 10.3 29 3,760 400 870 330 510

12% 0.52 13,000 1.87 12.6 35 7,620 930 1,360 430 830

Pine

Eastern white Green 0.34 4,900 0.99 5.2 17 2,440 220 680 250 290

12% 0.35 8,600 1.24 6.8 18 4,800 440 900 310 380

Jack Green 0.40 6,000 1.07 7.2 26 2,950 300 750 360 400

12% 0.43 9,900 1.35 8.3 27 5,660 580 1,170 420 570

Loblolly Green 0.47 7,300 1.40 8.2 30 3,510 390 860 260 450

12% 0.51 12,800 1.79 10.4 30 7,130 790 1,390 470 690

Lodgepole Green 0.38 5,500 1.08 5.6 20 2,610 250 680 220 330

12% 0.41 9,400 1.34 6.8 20 5,370 610 880 290 480

Longleaf Green 0.54 8,500 1.59 8.9 35 4,320 480 1,040 330 590

12% 0.59 14,500 1.98 11.8 34 8,470 960 1,510 470 870

Pitch Green 0.47 6,800 1.20 9.2 — 2,950 360 860 — —

12% 0.52 10,800 1.43 9.2 — 5,940 820 1,360 — —

General Technical Report FPL–GTR–190

Chapter 5 Mechanical Properties of Wood

5–13

Table 5–3b. Strength properties of some commercially important woods grown in the United States (inch–pound)

a

—con.

Static bending

Impact

bending

(in.)

Com-

pression

parallel

to grain

(lbf in

–2

)

Com-

pression

perpen-

dicular

to grain

(lbf in

–2

)

Shear

parallel

to

grain

(lbf in

–2

)

Tension

perpen-

dicular

to grain

(lbf in

–2

)

Side

hard-

ness

(lbf)

Modulus

of

rupture

(lbf in

–2

)

Modulus

of

elasticity

c

(10

6

lbf in

–2

)

Work

to

maxi-

mum

load

(in-lbf in

–3

)

Common species

names

Moisture

content

Specific

gravity

b

Pine—con.

Pond Green 0.51 7,400 1.28 7.5 — 3,660 440 940 — —

12% 0.56 11,600 1.75 8.6 — 7,540 910 1,380 — —

Ponderosa Green 0.38 5,100 1.00 5.2 21 2,450 280 700 310 320

12% 0.40 9,400 1.29 7.1 19 5,320 580 1,130 420 460

Red Green 0.41 5,800 1.28 6.1 26 2,730 260 690 300 340

12% 0.46 11,000 1.63 9.9 26 6,070 600 1,210 460 560

Sand Green 0.46 7,500 1.02 9.6 — 3,440 450 1,140 — —

12% 0.48 11,600 1.41 9.6 — 6,920 836 — — —

Shortleaf Green 0.47 7,400 1.39 8.2 30 3,530 350 910 320 440

12% 0.51 13,100 1.75 11.0 33 7,270 820 1,390 470 690

Slash Green 0.54 8,700 1.53 9.6 — 3,820 530 960 — —

12% 0.59 16,300 1.98 13.2 — 8,140 1,020 1,680 — —

Spruce Green 0.41 6,000 1.00 — — 2,840 280 900 — 450

12% 0.44 10,400 1.23 — — 5,650 730 1,490 — 660

Sugar Green 0.34 4,900 1.03 5.4 17 2,460 210 720 270 270

12% 0.36 8,200 1.19 5.5 18 4,460 500 1,130 350 380

Virginia Green 0.45 7,300 1.22 10.9 34 3,420 390 890 400 540

12% 0.48 13,000 1.52 13.7 32 6,710 910 1,350 380 740

Western white Green 0.35 4,700 1.19 5.0 19 2,430 190 680 260 260

12% 0.38 9,700 1.46 8.8 23 5,040 470 1,040 — 420

Redwood

Old-growth Green 0.38 7,500 1.18 7.4 21 4,200 420 800 260 410

12% 0.40 10,000 1.34 6.9 19 6,150 700 940 240 480

Young-growth Green 0.34 5,900 0.96 5.7 16 3,110 270 890 300 350

12% 0.35 7,900 1.10 5.2 15 5,220 520 1,110 250 420

Spruce

Black Green 0.38 6,100 1.38 7.4 24 2,840 240 740 100 340

12% 0.42 10,800 1.61 10.5 23 5,960 550 1,230 — 530

Engelmann Green 0.33 4,700 1.03 5.1 16 2,180 200 640 240 260

12% 0.35 9,300 1.30 6.4 18 4,480 410 1,200 350 390

Red Green 0.37 6,000 1.33 6.9 18 2,720 260 750 220 340

12% 0.40 10,800 1.66 8.4 25 5,540 550 1,290 350 530

Sitka Green 0.37 5,700 1.23 6.3 24 2,670 280 760 250 350

12% 0.40 10,200 1.57 9.4 25 5,610 580 1,150 370 510

White Green 0.33 5,000 1.14 6.0 22 2,350 210 640 220 270

12% 0.36 9,400 1.43 7.7 20 5,180 430 970 360 410

Tamarack Green 0.49 7,200 1.24 7.2 28 3,480 390 860 260 380

12% 0.53 11,600 1.64 7.1 23 7,160 800 1,280 400 590

a

Results of tests on clear specimens in the green and air-dried conditions. Definition of properties: impact bending is height of drop that causes complete failure,

using 0.71-kg (50-lb) hammer; compression parallel to grain is also called maximum crushing strength; compression perpendicular to grain is fiber stress at

p

roportional limit; shear is maximum shearing strength; tension is maximum tensile strength; and side hardness is hardness measured when load is perpendicular

to grain.

b

Specific gravity is based on weight when ovendry and volume when green or at 12% moisture content.

c

Modulus of elasticity measured from a simply supported, center-loaded beam, on a span depth ratio of 14/1. To correct for shear deflection, the modulus can be

increased by 10%.

d

Values for side hardness of the true hickories are from Bendtsen and Ethington (1975).

e

Coast Douglas-fir is defined as Douglas-fir growing in Oregon and Washington State west of the Cascade Mountains summit. Interior West includes California

and all counties in Oregon and Washington east of, but adjacent to, the Cascade summit; Interior North, the remainder of Oregon and Washington plus Idaho,

Montana, and Wyoming; and Interior South, Utah, Colorado, Arizona, and New Mexico.

5–14

Table 5–4a. Mechanical properties of some commercially important woods grown in Canada and imported

into the United States (metric)

a

Static bending

Compression

parallel

to grain

(kPa)

Compression

perpendicular

to grain

(kPa)

Shear

parallel

to grain

(kPa)

Common species

names

Moisture

content

Specific

gravity

Modulus of

rupture

(kPa)

Modulus of

elasticity

(MPa)

Hardwoods

Aspen

Quaking Green 0.37 38,000 9,000 16,200 1,400 5,000

12% 68,000 11,200 36,300 3,500 6,800

Big-toothed Green 0.39 36,000 7,400 16,500 1,400 5,400

12% 66,000 8,700 32,800 3,200 7,600

Cottonwood

Balsam, poplar Green 0.37 34,000 7,900 14,600 1,200 4,600

12% 70,000 11,500 34,600 2,900 6,100

Black Green 0.30 28,000 6,700 12,800 700 3,900

12% 49,000 8,800 27,700 1,800 5,900

Eastern Green 0.35 32,000 6,000 13,600 1,400 5,300

12% 52,000 7,800 26,500 3,200 8,000

Softwoods

Cedar

Northern white Green 0.30 27,000 3,600 13,000 1,400 4,600

12% 42,000 4,300 24,800 2,700 6,900

Western redcedar Green 0.31 36,000 7,200 19,200 1,900 4,800

12% 54,000 8,200 29,600 3,400 5,600

Yellow Green 0.42 46,000 9,200 22,300 2,400 6,100

12% 80,000 11,000 45,800 4,800 9,200

Douglas-fir Green 0.45 52,000 11,100 24,900 3,200 6,300

12% 88,000 13,600 50,000 6,000 9,500

Fir

Subalpine Green 0.33 36,000 8,700 17,200 1,800 4,700

12% 56,000 10,200 36,400 3,700 6,800

Pacific silver Green 0.36 38,000 9,300 19,100 1,600 4,900

12% 69,000 11,300 40,900 3,600 7,500

Balsam Green 0.34 36,000 7,800 16,800 1,600 4,700

12% 59,000 9,600 34,300 3,200 6,300

Hemlock

Eastern Green 0.40 47,000 8,800 23,600 2,800 6,300

12% 67,000 9,700 41,200 4,300 8,700

Western Green 0.41 48,000 10,200 24,700 2,600 5,200

12% 81,000 12,300 46,700 4,600 6,500

Larch, western Green 0.55 60,000 11,400 30,500 3,600 6,300

12% 107,000 14,300 61,000 7,300 9,200

Pine

Eastern white Green 0.36 35,000 8,100 17,900 1,600 4,400

12% 66,000 9,400 36,000 3,400 6,100

Jack Green 0.42 43,000 8,100 20,300 2,300 5,600

12% 78,000 10,200 40,500 5,700 8,200

Lodgepole Green 0.40 39,000 8,800 19,700 1,900 5,000

12% 76,000 10,900 43,200 3,600 8,500

Ponderosa Green 0.44 39,000 7,800 19,600 2,400 5,000

12% 73,000 9,500 42,300 5,200 7,000

Red Green 0.39 34,000 7,400 16,300 1,900 4,900

12% 70,000 9,500 37,900 5,200 7,500

Western white Green 0.36 33,000 8,200 17,400 1,600 4,500

12% 64,100 10,100 36,100 3,200 6,300

Spruce

Black Green 0.41 41,000 9,100 19,000 2,100 5,500

12% 79,000 10,500 41,600 4,300 8,600

General Technical Report FPL–GTR–190

of clear wood parallel to grain. Table 5–7 lists average ten-

sile strength values for a limited number of specimens of a

few species. In the absence of sufcient tension test data,

modulus of rupture values are sometimes substituted for

tensile strength of small, clear, straight-grained pieces of

wood. The modulus of rupture is considered to be a low or

conservative estimate of tensile strength for clear specimens

(this is not true for lumber).

Less Common Properties

Strength properties less commonly measured in clear wood

include torsion, toughness, rolling shear, and fracture

toughness. Other properties involving time under load

include creep, creep rupture or duration of load, and fatigue

strength.

Torsion strength—Resistance to twisting about a longitu-

dinal axis. For solid wood members, torsional shear strength

may be taken as shear strength parallel to grain. Two-thirds

of the value for torsional shear strength may be used as an

estimate of the torsional shear stress at the proportional

limit.

Toughness—Energy required to cause rapid complete fail-

ure in a centrally loaded bending specimen. Tables 5–8 and

5–9 give average toughness values for samples of a few

hardwood and softwood species. Average coefcients of

variation for toughness as determined from approximately

50 species are shown in Table 5–6.

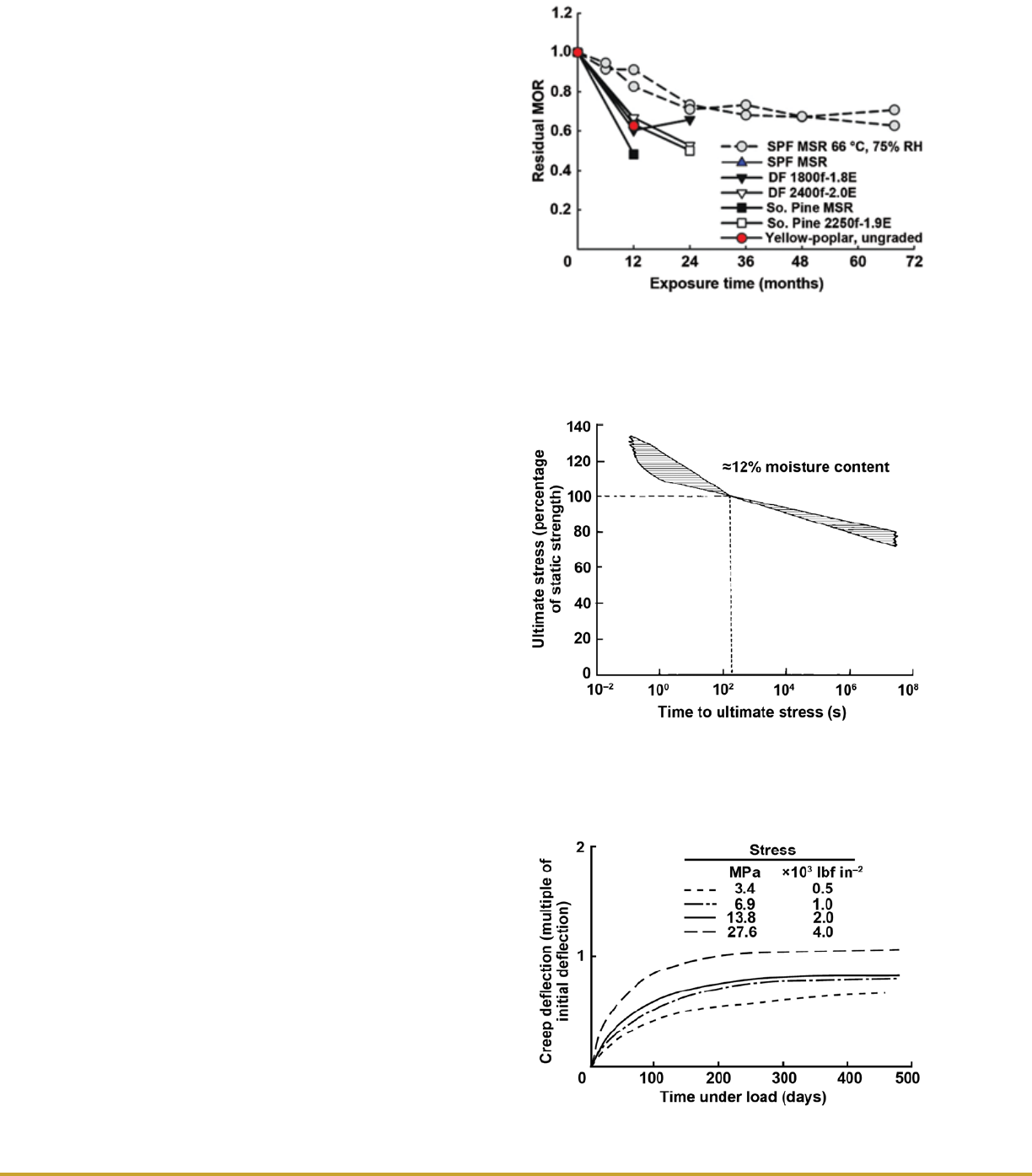

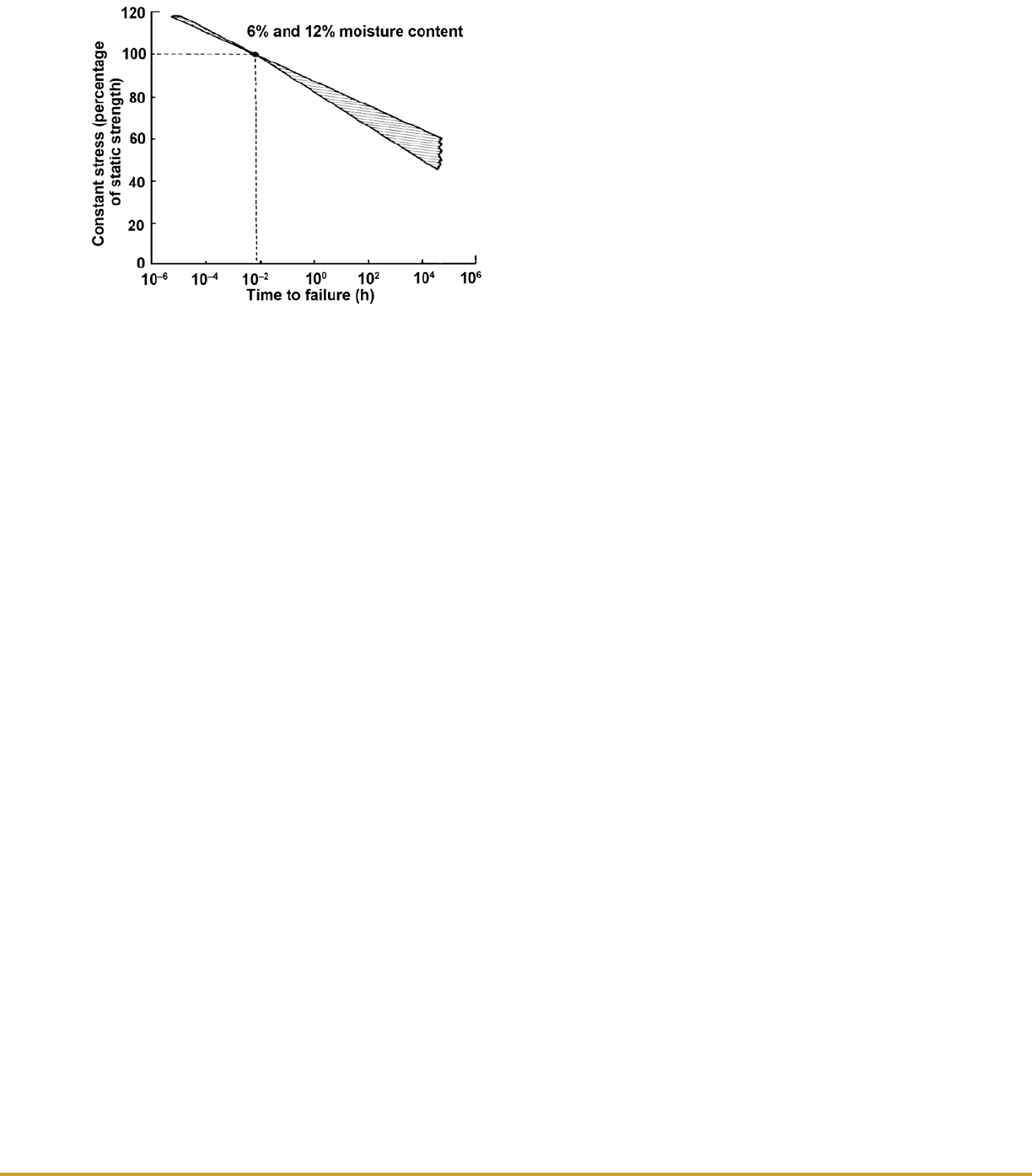

Creep and duration of load—Time-dependent deformation

of wood under load. If the load is sufciently high and the

duration of load is long, failure (creep–rupture) will eventu-

ally occur. The time required to reach rupture is commonly

called duration of load. Duration of load is an important fac-

tor in setting design values for wood. Creep and duration of

load are described in later sections of this chapter.

Fatigue—Resistance to failure under specic combina-

tions of cyclic loading conditions: frequency and number

of cycles, maximum stress, ratio of maximum to minimum

stress, and other less-important factors. The main factors

affecting fatigue in wood are discussed later in this chapter.

The discussion also includes interpretation of fatigue data

and information on fatigue as a function of the service

environment.

Rolling shear strength—Shear strength of wood where

shearing force is in a longitudinal plane and is acting per-

pendicular to the grain. Few test values of rolling shear in

solid wood have been reported. In limited tests, rolling shear

strength averaged 18% to 28% of parallel-to-grain shear

values. Rolling shear strength is about the same in the longi-

tudinal–radial and longitudinal–tangential planes.

Nanoindentation hardness—This type of hardness mea-

surement is conducted at the nanometer scale (the scale of

the cell wall). Nanoindentation uses an extremely small

indenter of a hard material and specied shape (usually a

pyramid) to press into the surface with sufcient force that

the wood deforms. The load and deformation history is used

to develop mechanical property information. Nanoinden-

tion hardness provides a method for describing a material’s

response to various applied loading conditions at a scale that

may explain differences in wood cell structures and help

predict material performance after chemical treatments have

been applied (Moon and others 2006).

Fracture toughness—Ability of wood to withstand aws

that initiate failure. Measurement of fracture toughness

helps identify the length of critical aws that initiate failure

in materials.

To date, there is no standard test method for determining

fracture toughness in wood. Three types of stress elds, and

Chapter 5 Mechanical Properties of Wood

5–15

Table 5

–

4a. Mechanical properties of some commercially important woods grown in Canada and imported

into the United States (metric)

a

—con.

Common species

names

Moisture

content

Specific

gravity

Static bending

Compression

parallel

to grain

(kPa)

Compression

perpendicular

to grain

(kPa)

Shear

parallel

to grain

(kPa)

Modulus of

rupture

(kPa)

Modulus of

elasticity

(MPa)

Engelmann Green 0.38 39,000 8,600 19,400 1,900 4,800

12% 70,000 10,700 42,400 3,700 7,600

Red Green 0.38 41,000 9,100 19,400 1,900 5,600

12% 71,000 11,000 38,500 3,800 9,200

Sitka Green 0.35 37,000 9,400 17,600 2,000 4,300

12% 70,000 11,200 37,800 4,100 6,800

White Green 0.35 35,000 7,900 17,000 1,600 4,600

12% 63,000 10,000 37,000 3,400 6,800

Tamarack Green 0.48 47,000 8,600 21,600 2,800 6,300

12% 76,000 9,400 44,900 6,200 9,000

a

Results of tests on clear, straight-grained specimens. Property values based on ASTM Standard D 2555–88. Information on additional

p

roperties can be obtained from Department of Forestry, Canada, Publication No. 1104. For each species, values in the first line are from tests

of green material; those in the second line are adjusted from the green condition to 12% moisture content using dry to green clear wood

p

roperty ratios as

r

eported in ASTM D 2555–88. Specific gravity is based on weight when ovendry and volume when green.

5–16

Table 5–4b. Mechanical properties of some commercially important woods grown in Canada and imported

into the United States (inch–pound)

a

Static bending

Compression

parallel to

grain

(lbf in

–2

)

Compression

perpendicular

to grain

(lbf in

–2

)

Shear

parallel to

grain

(lbf in

–2

)

Common species

names

Moisture

content

Specific

gravity

Modulus of

rupture

(lbf in

–2

)

Modulus of

elasticity

(10

6

lbf in

–2

)

Hardwoods

Aspen

Quaking Green 0.37 5,500 1.31 2,350 200 720

12% 9,800 1.63 5,260 510 980

Bigtooth Green 0.39 5,300 1.08 2,390 210 790

12% 9,500 1.26 4,760 470 1,100

Cottonwood

Balsam, poplar Green 0.37 5,000 1.15 2,110 180 670

12% 10,100 1.67 5,020 420 890

Black Green 0.30 4,100 0.97 1,860 100 560

12% 7,100 1.28 4,020 260 860

Eastern Green 0.35 4,700 0.87 1,970 210 770

12% 7,500 1.13 3,840 470 1,160

Softwoods

Cedar

Northern white Green 0.30 3,900 0.52 1,890 200 660

12% 6,100 0.63 3,590 390 1,000

Western redcedar Green 0.31 5,300 1.05 2,780 280 700

12% 7,800 1.19 4,290 500 810

Yellow Green 0.42 6,600 1.34 3,240 350 880

12% 11,600 1.59 6,640 690 1,340

Douglas-fir Green 0.45 7,500 1.61 3,610 460 920

12% 12,800 1.97 7,260 870 1,380

Fir

Balsam Green 0.34 5,300 1.13 2,440 240 680

12% 8,500 1.40 4,980 460 910

Pacific silver Green 0.36 5,500 1.35 2,770 230 710

12% 10,000 1.64 5,930 520 1,190

Subalpine Green 0.33 5,200 1.26 2,500 260 680

12% 8,200 1.48 5,280 540 980

Hemlock

Eastern Green 0.40 6,800 1.27 3,430 400 910

12% 9,700 1.41 5,970 630 1,260

Western Green 0.41 7,000 1.48 3,580 370 750

12% 11,800 1.79 6,770 660 940

Larch, western Green 0.55 8,700 1.65 4,420 520 920

12% 15,500 2.08 8,840 1,060 1,340

Pine

Eastern white Green 0.36 5,100 1.18 2,590 240 640

12% 9,500 1.36 5,230 490 880

Jack Green 0.42 6,300 1.17 2,950 340 820

12% 11,300 1.48 5,870 830 1,190

Lodgepole Green 0.40 5,600 1.27 2,860 280 720

12% 11,000 1.58 6,260 530 1,240

Ponderosa Green 0.44 5,700 1.13 2,840 350 720

12% 10,600 1.38 6,130 760 1,020

Red Green 0.39 5,000 1.07 2,370 280 710

12% 10,100 1.38 5,500 720 1,090

Western white Green 0.36 4,800 1.19 2,520 240 650

12% 9,300 1.46 5,240 470 920

Spruce

Black Green 0.41 5,900 1.32 2,760 300 800

12% 11,400 1.52 6,040 620 1,250

Engelmann Green 0.38 5,700 1.25 2,810 270 700

12% 10,100 1.55 6,150 540 1,100

Red Green 0.38 5,900 1.32 2,810 270 810

12% 10,300 1.60 5,590 550 1,330

General Technical Report FPL–GTR–190

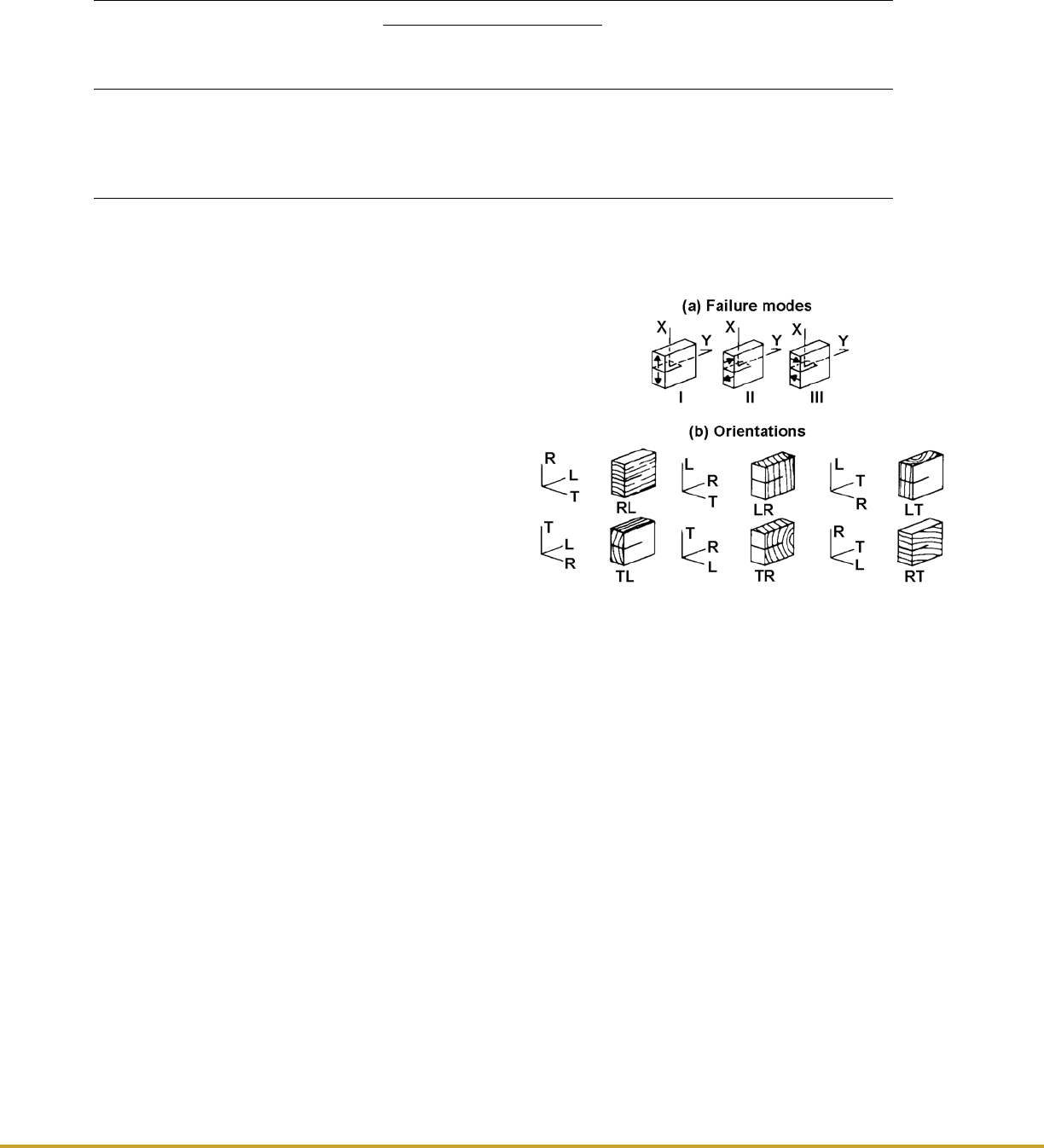

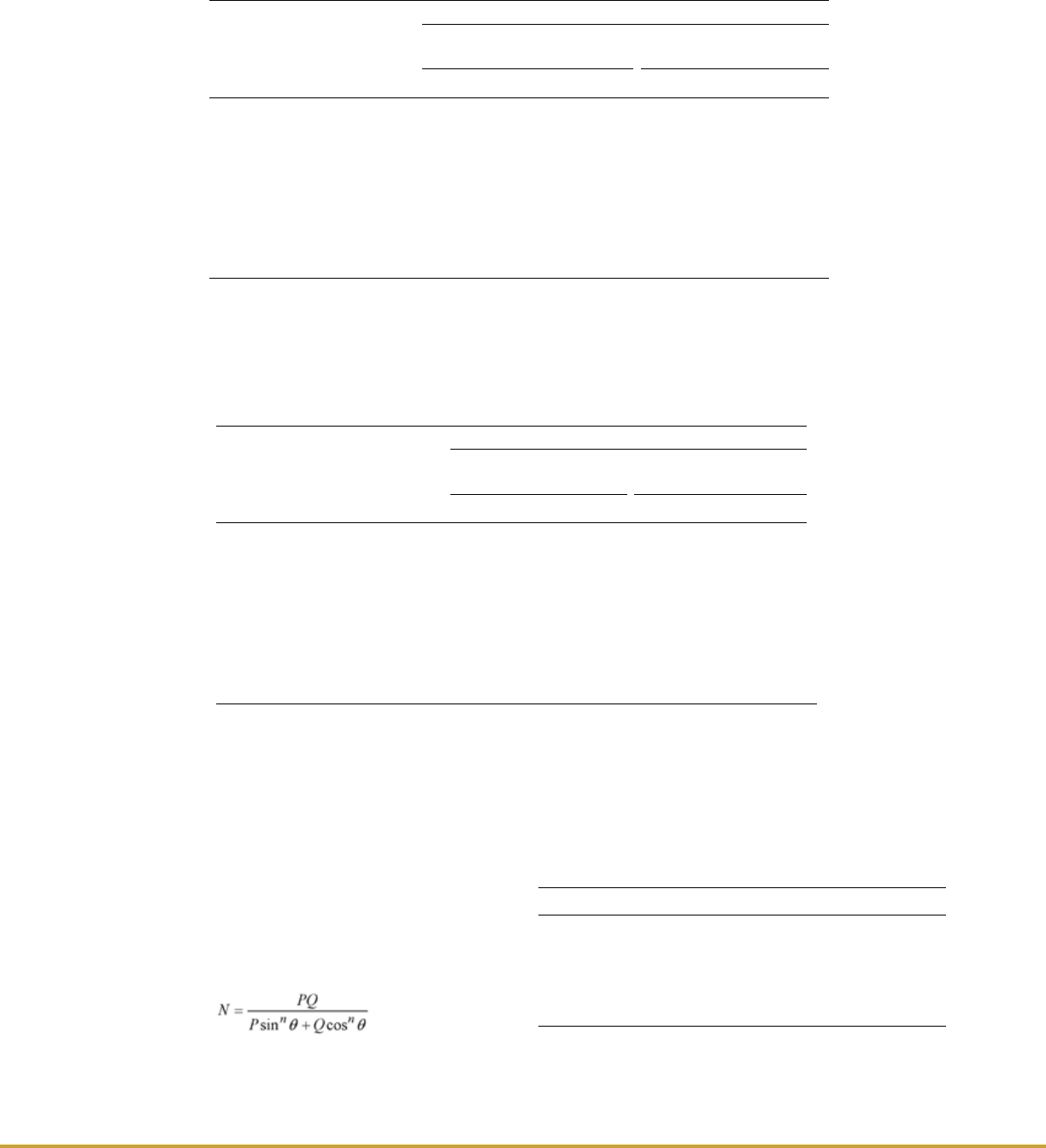

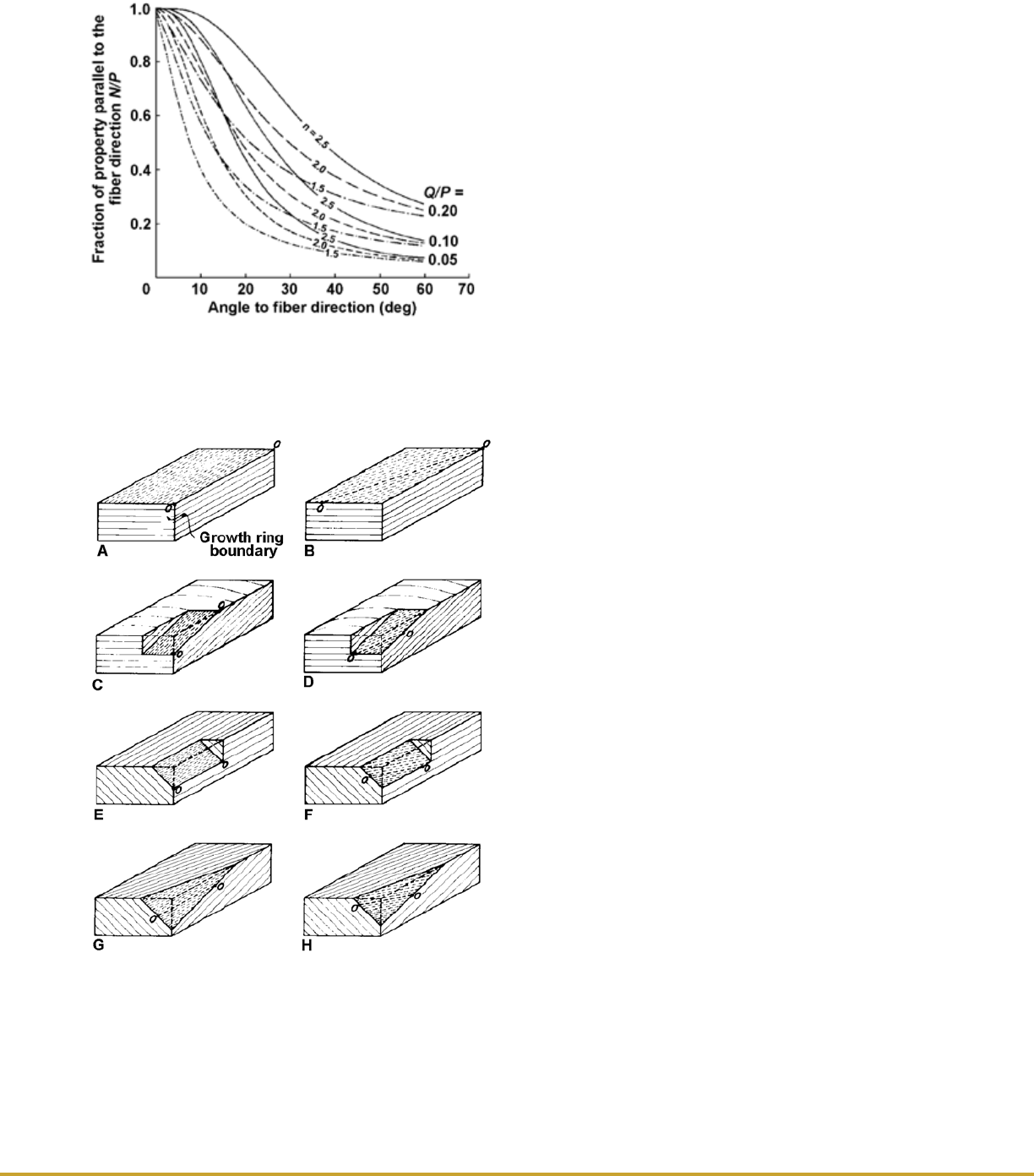

associated stress intensity factors, can be dened at a crack

tip: opening mode (I), forward shear mode (II), and trans-

verse shear mode (III) (Fig. 5–2a). A crack may lie in one of

these three planes and may propagate in one of two direc-

tions in each plane. This gives rise to six crack-propagation

systems (RL, TL, LR, TR, LT, and RT) (Fig. 5–2b). Of these

crack-propagation systems, four systems are of practical

importance: RL, TL, TR, and RT. Each of these four systems

allow for propagation of a crack along the lower strength

path parallel to the grain. The RL and TL orientations in

wood (where R or T is perpendicular to the crack plane

and L is the direction in which the crack propagates) will

predominate as a result of the low strength and stiffness of

wood perpendicular to the grain. It is therefore one of these

two orientations that is most often tested. Values for mode I

fracture toughness range from 220 to 550 kPa m

1/2

(200 to

500 lbf in

–2

in

1/2

) and for mode II range from 1,650 to

2,400 kPa m

1/2

(1,500 to 2,200 lbf in

–2

in

1/2

). Table 5–10

summarizes selected mode I and mode II test results at 10%

to 12% moisture content available in the literature. The

limited information available on moisture content effects on

fracture toughness suggests that fracture toughness is either

insensitive to moisture content or increases as the material

dries, reaching a maximum between 6% and 15% moisture

content; fracture toughness then decreases with further

drying.

Vibration Properties

The vibration properties of primary interest in structural

materials are speed of sound and internal friction (damping

capacity).

Speed of Sound

The speed of sound in a structural material is a function of

the modulus of elasticity and density. In wood, the speed of

sound also varies with grain direction because the transverse

modulus of elasticity is much less than the longitudinal

value (as little as 1/20); the speed of sound across the grain

is about one-fth to one-third of the longitudinal value.

For example, a piece of wood with a longitudinal modulus

of elasticity of 12.4 GPa (1.8 × 10

6

lbf in

–2

) and density of

480 kg m

–3

(30 lb ft

–3

) would have a speed of sound in the

longitudinal direction of about 3,800 m s

–1

(12,500 ft s

–1

).

In the transverse direction, modulus of elasticity would be

about 690 MPa (100 × 10

3

lbf in

–2

) and the speed of sound

approximately 890 m s

–1

(2,900 ft s

–1

).

The speed of sound decreases with increasing temperature

or moisture content in proportion to the inuence of these

variables on modulus of elasticity and density. The speed of

sound decreases slightly with increasing frequency and am-

plitude of vibration, although for most common applications

this effect is too small to be signicant. There is no recog-

nized independent effect of species on the speed of sound.

Variability in the speed of sound in wood is directly related

to the variability of modulus of elasticity and density.

Internal Friction

When solid material is strained, some mechanical energy

is dissipated as heat. Internal friction is the term used to

denote the mechanism that causes this energy dissipation.

Chapter 5 Mechanical Properties of Wood

5–17

Table 5

–

4b. Mechanical properties of some commercially important woods grown in Canada and imported

into the United States (inch–pound)

a

—con.

Common species

names

Moisture

content

Specific

gravity

Static bending

Compression

parallel to

grain

(lbf in

–2

)

Compression

perpendicular

to grain

(lbf in

–2

)

Shear

parallel to

grain

(lbf in

–2

)

Modulus of

rupture

(lbf in

–2

)

Modulus of

elasticity

(10

6

lbf in

–2

)

Sitka Green 0.35 5,400 1.37 2,560 290 630

12% 10,100 1.63 5,480 590 980

White Green 0.35 5,100 1.15 2,470 240 670

12% 9,100 1.45 5,360 500 980

Tamarack Green 0.48 6,800 1.24 3,130 410 920

12% 11,000 1.36 6,510 900 1,300

a

Results of tests on clear, straight-grained specimens. Property values based on ASTM Standard D 2555–88. Information on additional properties

can be obtained from Department of Forestry, Canada, Publication No. 1104. For each species, values in the first line are from tests of green

material; those in the second line are adjusted from the green condition to 12% moisture content using dry to green clear wood property ratios as

reported in ASTM D 2555–88. Specific gravity is based on weight when ovendry and volume when green.

Figure 5–2. Possible crack propagation systems for

wood.

5–18

Table 5–5a. Mechanical properties of some woods imported into the United States other than Canadian imports

(metric)

a

Static bending

Com-

pression

parallel

to grain

(kPa)

Shear

parallel

to grain

(kPa)

Side

hard-

ness

(N)

Sample

origin

b

Common and

botanical names

of species

Moisture

content

Specific

gravity

Modulus

of

rupture

(kPa)

Modulus

of

elasticity

(MPa)

Work to

maximum

load

(kJ m

–3

)

Afrormosia (Pericopsis elata) Green 0.61 102,000 12,200 135 51,600 11,500 7,100 AF

12% 126,900 13,400 127 68,500 14,400 6,900

Albarco (Cariniana spp.) Green 0.48 — — — — — — AM

12% 100,000 10,300 95 47,000 15,900 4,500

Andiroba (Carapa guianensis) Green 0.54 71,000 11,700 68 33,000 8,400 3,900 AM

12% — 106,900 13,800 97 56,000 10,400 5,000

Angelin (Andira inermis) Green 0.65 — — — — — — AF

12% 124,100 17,200 — 63,400 12,700 7,800

Angelique (Dicorynia

guianensis)

Green 0.6 78,600 12,700 83 38,500 9,200 4,900 AM

12% — 120,000 15,100 105 60,500 11,400 5,700

Avodire (Turraeanthus

africanus)

Green 0.48 — — — — — — AF

12% 87,600 10,300 65 49,300 14,000 4,800

Azobe (Lophira alata) Green 0.87 116,500 14,900 83 65,600 14,100 12,900 AF

12% 168,900 17,000 — 86,900 20,400 14,900

Balsa (Ochroma pyramidale) Green 0.16 — — — — — — AM

12% 21,600 3,400 14 14,900 2,100 —

Banak (Virola spp.) Green 0.42 38,600 11,300 28 16,500 5,000 1,400 AM

12% — 75,200 14,100 69 35,400 6,800 2,300

Benge (Guibourtia arnoldiana) Green 0.65 — — — — — — AF

12% 147,500 14,100 — 78,600 14,400 7,800

Bubinga (Guibourtia spp.) Green 0.71 — — — — — — AF

12% 155,800 17,100 — 72,400 21,400 12,000

Bulletwood (Manilkara Green 0.85 119,300 18,600 94 59,900 13,100 9,900 AM

bidentata) 12% 188,200 23,800 197 80,300 17,200 14,200

Cativo (Prioria copaifera) Green 0.4 40,700 6,500 37 17,000 5,900 2,000 AM

12% — 59,300 7,700 50 29,600 7,300 2,800

Ceiba (Ceiba pentandra) Green 0.25 15,200 2,800 8 7,300 2,400 1,000 AM

12% 29,600 3,700 19 16,400 3,800 1,100

Courbaril (Hymenaea Green 0.71 88,900 12,700 101 40,000 12,200 8,800 AM

courbaril) 12% — 133,800 14,900 121 65,600 17,000 10,500

Cuangare (Dialyanthera spp.) Green 0.31 27,600 7,000 — 14,300 4,100 1,000 AM

12% 50,300 10,500 — 32,800 5,700 1,700

Cypress, Mexican (Cupressus Green 0.39 42,700 6,300 — 19,900 6,600 1,500 AF

lustianica) 12% 71,000 7,000 — 37,100 10,900 2,000

Degame (Calycophyllum Green 0.67 98,600 13,300 128 42,700 11,400 7,300 AM

candidissimum) 12% 153,800 15,700 186 66,700 14,600 8,600

Determa (Ocotea rubra) Green 0.52 53,800 10,100 33 25,900 5,900 2,300 AM

12% 72,400 12,500 44 40,000 6,800 2,900

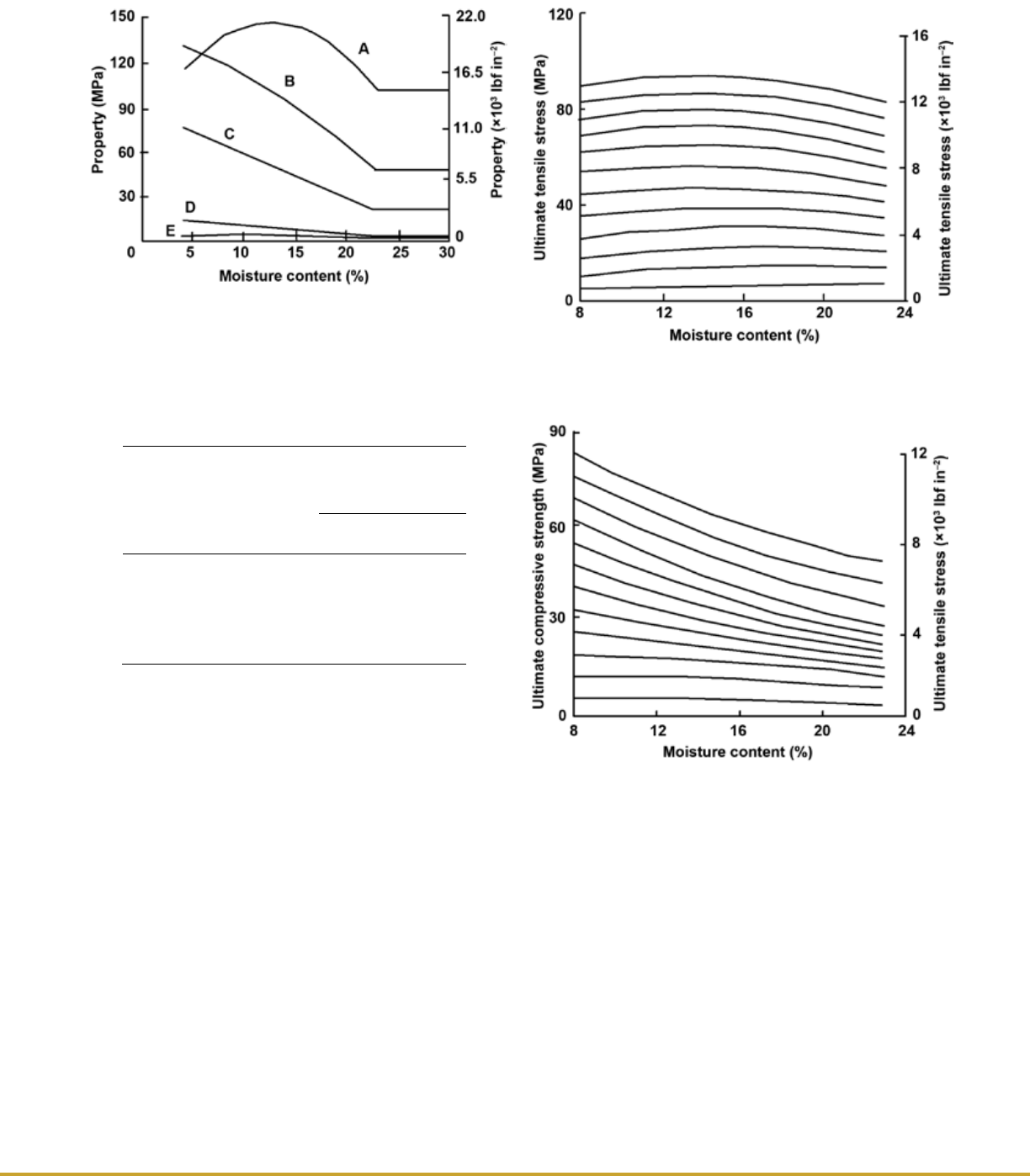

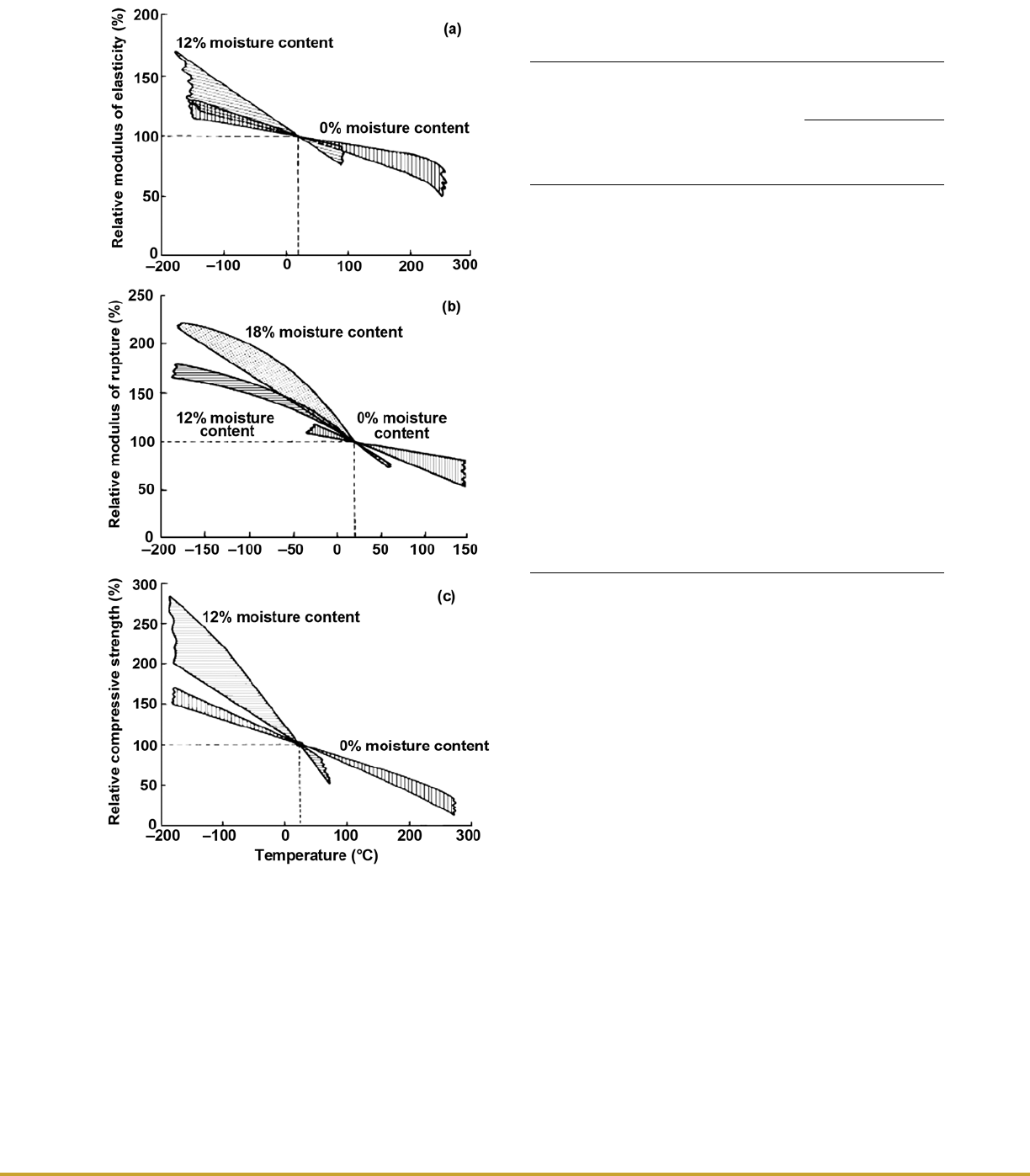

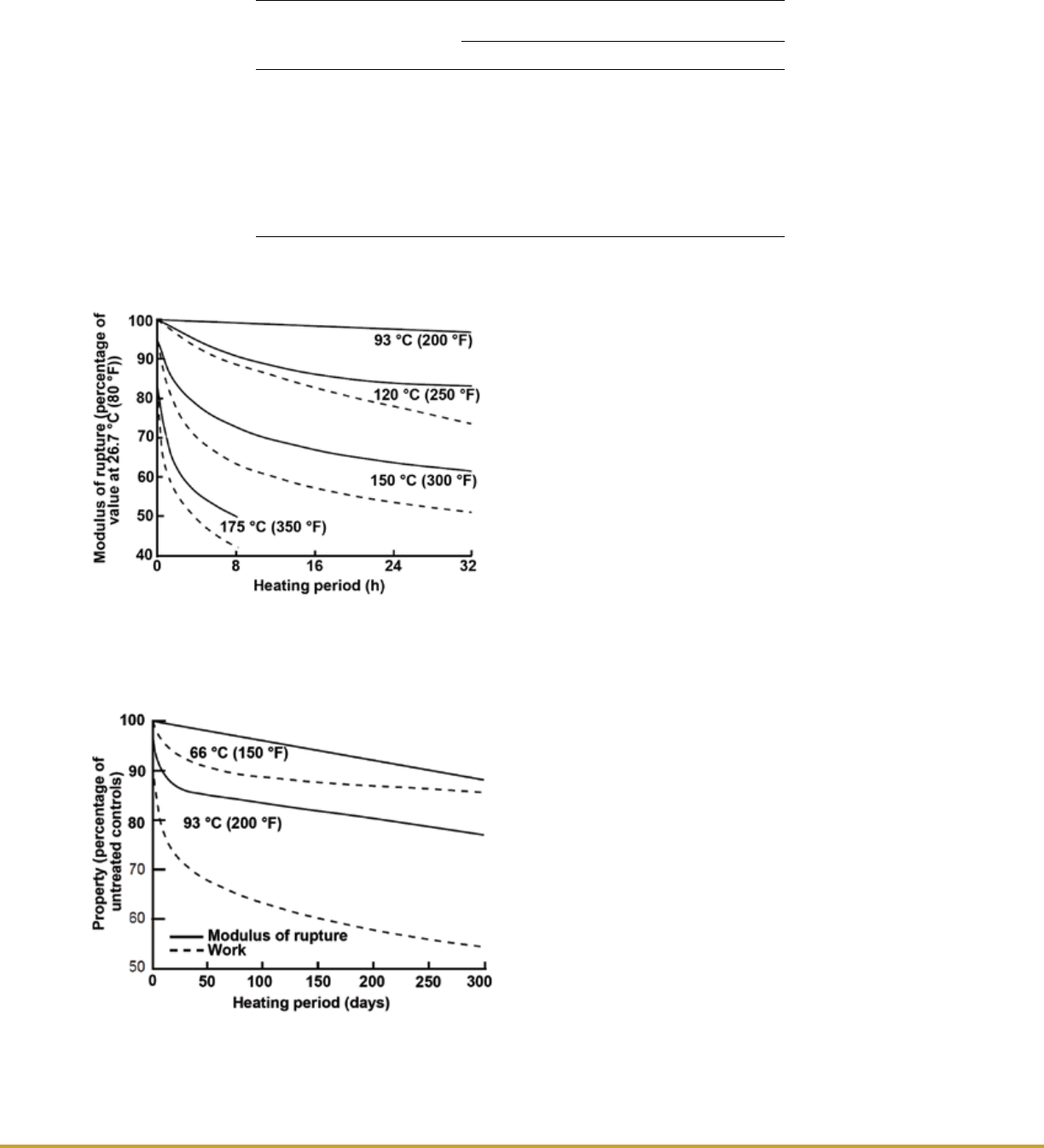

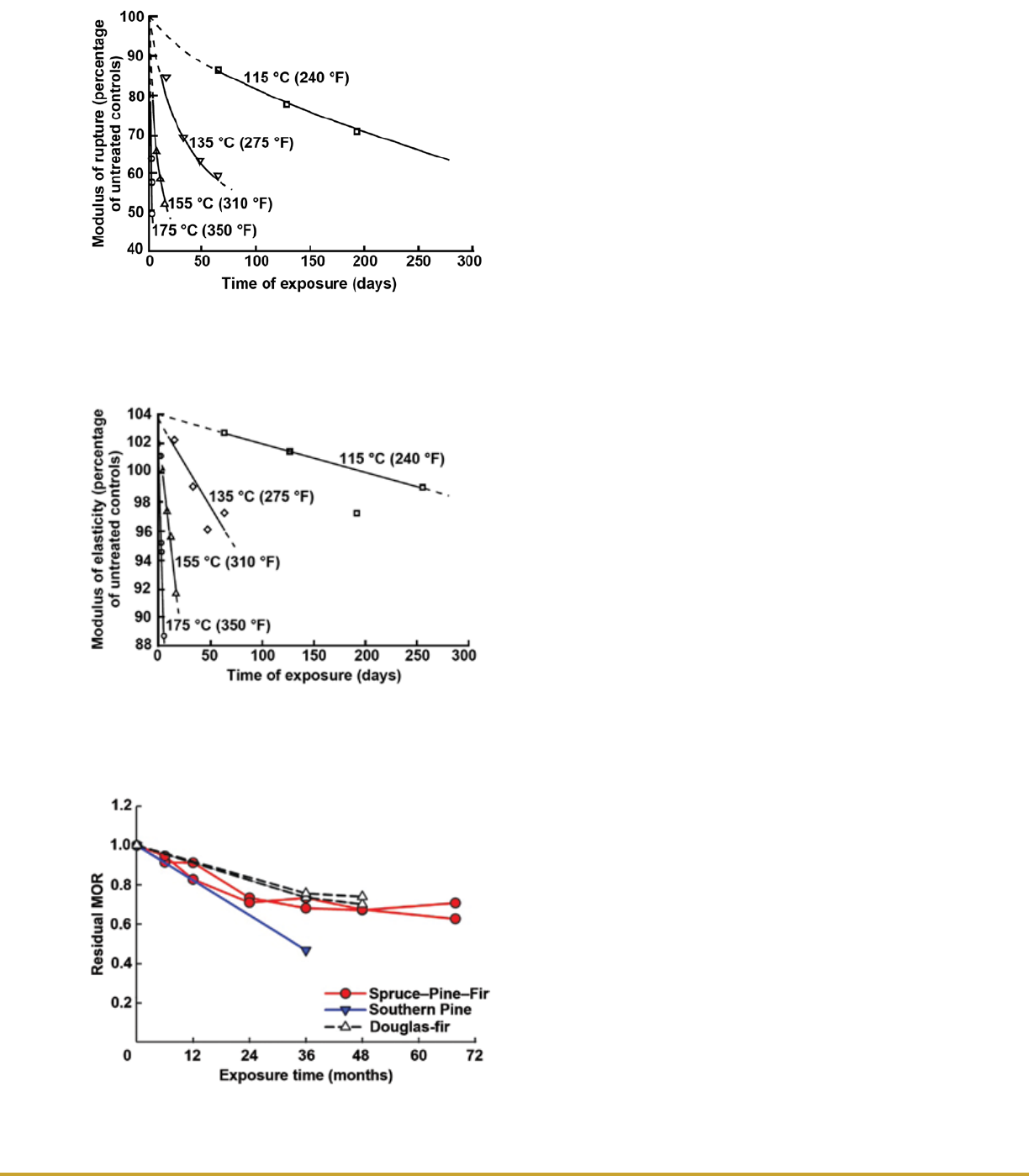

Ekop (Tetraberlinia Green 0.6 — — — — — — AF